IMB-CNM develops innovative power electronics components to improve electric vehicle performance

Within the framework of the European SCAPE project, the Institute of Microelectronics of Barcelona is researching and developing new proposals for the integration of power electronic circuits in electric vehicles. For power converters, they have developed a novel modular, scalable and compact structure, which reduces costs and improves performance. All in a more sustainable process.

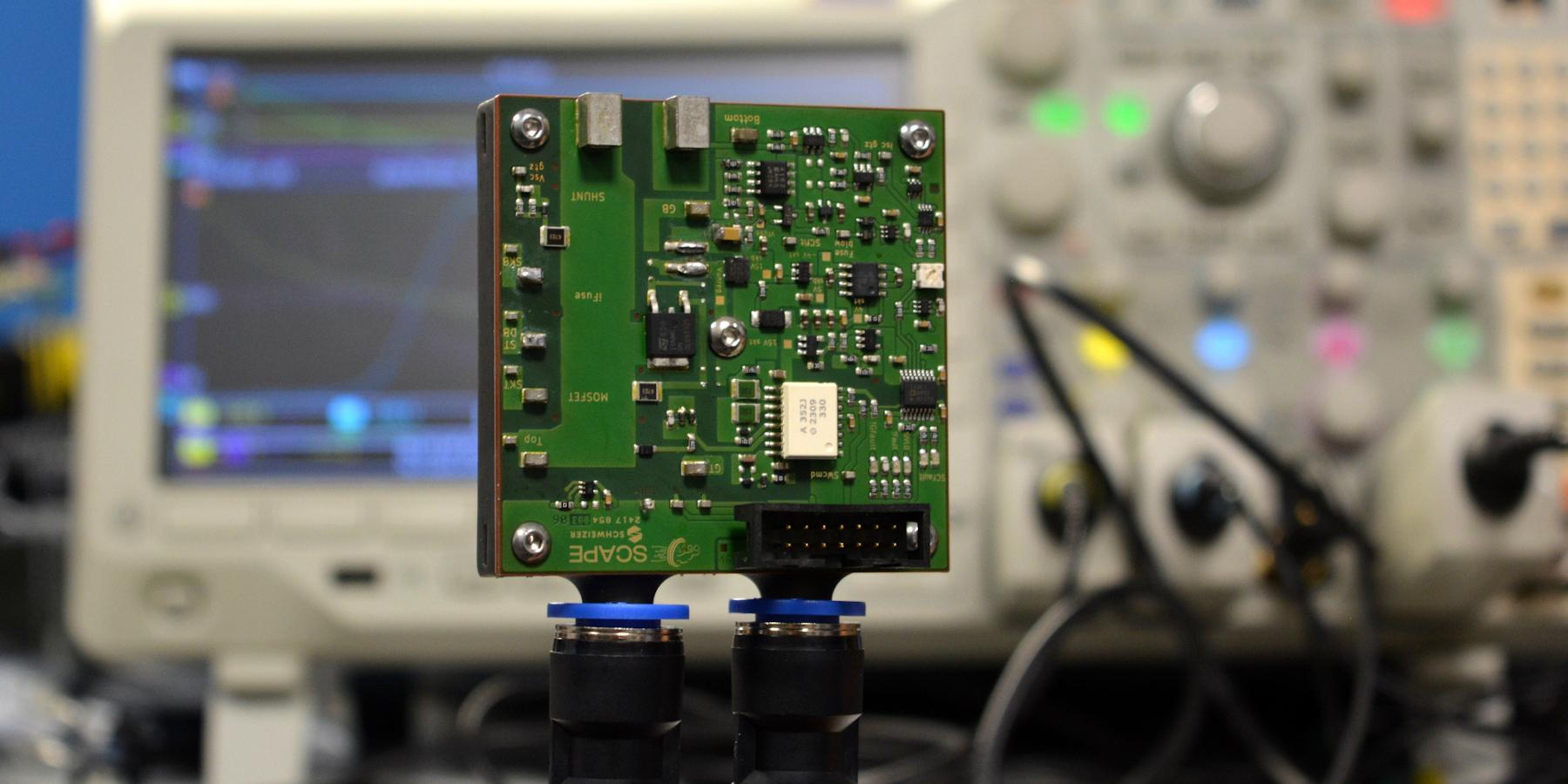

Prototype switching cell developed in the SCAPE project with the chip-embedding technique, the tubes of the liquid cooling system can be seen. Credit: Sabela Rey Cao.

The Institute of Microelectronics of Barcelona of the CSIC (IMB-CNM-CSIC) has developed the prototype of a new switching cell for electric vehicles. This cell will allow more efficient adaptation and control of power flows between energy sources and their loads, such as between the battery and the engine. The SCAPE project, funded by the European Union's Horizon Europe Program, brings together nine research institutions and companies from five European countries to develop new modular and scalable electronic components for the powertrain of future electric vehicles.

The transition to more sustainable and less polluting electric mobility and transport models is one of the priorities of European research. To support this, SCAPE (Switching-cell-array-based power electronics conversion for future electric vehicles) is focused on proposing and validating a novel design and architecture for the powertrain of electric vehicles, ranging from motorcycles to trucks. One of the ways to achieve this is the modular and standardizable design of power converters.

“We propose a completely novel, modular, scalable and compact switching cell structure implemented with chip-embedding technology. The chips of the power semiconductor devices are integrated inside the printed circuit boards or PCBs of the converter, instead of being soldered externally as it has been done so far in conventional technologies. This provides greater miniaturization and improved performance,” says Xavier Jordà, IMB-CNM principal investigator on the project and member of the Power Devices and Systems Group (PDS).

“The combination of several of these cells, in the manner of LEGO pieces, will facilitate the implementation of the electronic circuits needed for the traction of all types of electric vehicles,” he adds. This concept of standardized modular components will enable manufacturing at scale, generating fewer different processes and resulting in more cost-effective components.

More efficient, robust and sustainable power electronics

In order to introduce the power chips inside the structure of the boards, it has been necessary to develop new interconnection processes for them in the Micro and Nanofabrication Clean Room of the IMB-CNM-CSIC, which has a Unique Scientific and Technical Infrastructure (ICTS) seal by the Ministry of Science, Innovation and Universities.

“We have developed a technique that allows the deposition of copper layers of several microns on the top electrodes of the silicon carbide MOSFET transistors used in the project. The bonding process of the bottom side of the chips has been studied and optimized by means of new materials composed of silver micro- and nanoparticles,” says Emma Solà, IMB-CNM predoctoral researcher on the project. The material thus provides better performance than the solder alloys used to date. In addition, adds Solà, “it avoids the use of lead, a metal that can present toxicity problems”.

Another challenge in this type of circuits is miniaturization, i.e., to be able to handle high voltage, current and power levels in a very small space. “The design of the switching cell structure is a critical process that requires consideration of a large number of electrical, thermal, mechanical and other aspects,” explains Mariana Raya, predoctoral researcher at IMB-CNM in the PDS group and author of the design of the prototypes developed at SCAPE.

Raya comments that, in order to achieve optimal designs, “it has been necessary to develop a reliable multiphysics simulation methodology (electrical, thermal, mechanical and electro-magnetic), which allows us to study the response of the prototypes before their manufacture and to correct the design until the desired optimal performance is obtained. The experimental results we have obtained with the first prototypes have validated this approach, in the real operating range of the switching cells up to 400V voltage and 50A current”.

In electronics, another challenge of current research is the reliability of the devices. “Obtaining high robustness and durability of the developed components is essential, not only to guarantee a reliable operation of the final electric vehicle, but also to reduce as much as possible the electronic waste that would be caused by the failure of the circuitry”, says Xavier Perpiñà, researcher of the PDS group at IMB-CNM who participates in the project.

The technologies developed have positioned IMB-CNM and CSIC in a privileged position at the European level for the development of high integration density power electronic systems, both for electric mobility and industrial electrification applications. The electrification of industrial processes based on fossil fuels by others based on electrical energy from renewable sources is one of the tools available to achieve the objectives of decarbonization of society. It is also one of the thematic areas of action contemplated in the Interdisciplinary Technological Platform TRANSENER of the CSIC, in which the institute participates.

“We propose a completely novel, modular, scalable and compact switching cell structure implemented with chip-embedding technology. The chips of the power semiconductor devices are integrated inside the printed circuit boards or PCBs of the converter, instead of being soldered externally as it has been done so far in conventional technologies. This provides greater miniaturization and improved performance.”

A consortium of international excellence

SCAPE, with funding until 2026, held its mid-project meeting last July at the IMB-CNM-CSIC facilities. The cells have been developed in close collaboration with the Power Electronics Research Group (GREP) of the Universitat Politècnica de Catalunya (UPC), responsible for the electronic schematics, with the French company DeepConcept, responsible for the cooling subsystems, and with the German Schweizer Electronic AG, manufacturer of advanced printed circuits. The project is coordinated by the Institut de Recerca en Energia de Catalunya (IREC) and also includes the companies TEKNE and AVL, as well as the University of Modena and Reggio Emilia (Unimore).

Gallery

- Prototype switching cell developed in the SCAPE project with the chip-embedding technique, the tubes of the liquid cooling system can be seen. Credit: Sabela Rey Cao.

- Cross-section of the SCAPE switching-cells where you can see the chips inside the PCB

- A 5x5 mm2 chip with two metallized zones with 10 µm copper ready to be included inside the multilayer PCB structure.

- Test converter circuit with two interconnected switching cells.

- Group photo of SCAPE members at the meeting held at IMB-CNM in July 2024.