Solar Orbiter probe captures unprecedented images of the Sun's south pole with IMB-CNM technology

The ESA and NASA mission is equipped with silicon carbide photodiodes designed and manufactured by IMB-CNM-CSIC in its Micro and Nanofabrication Clean Room. The new images will improve our understanding of the magnetic field and the solar cycle

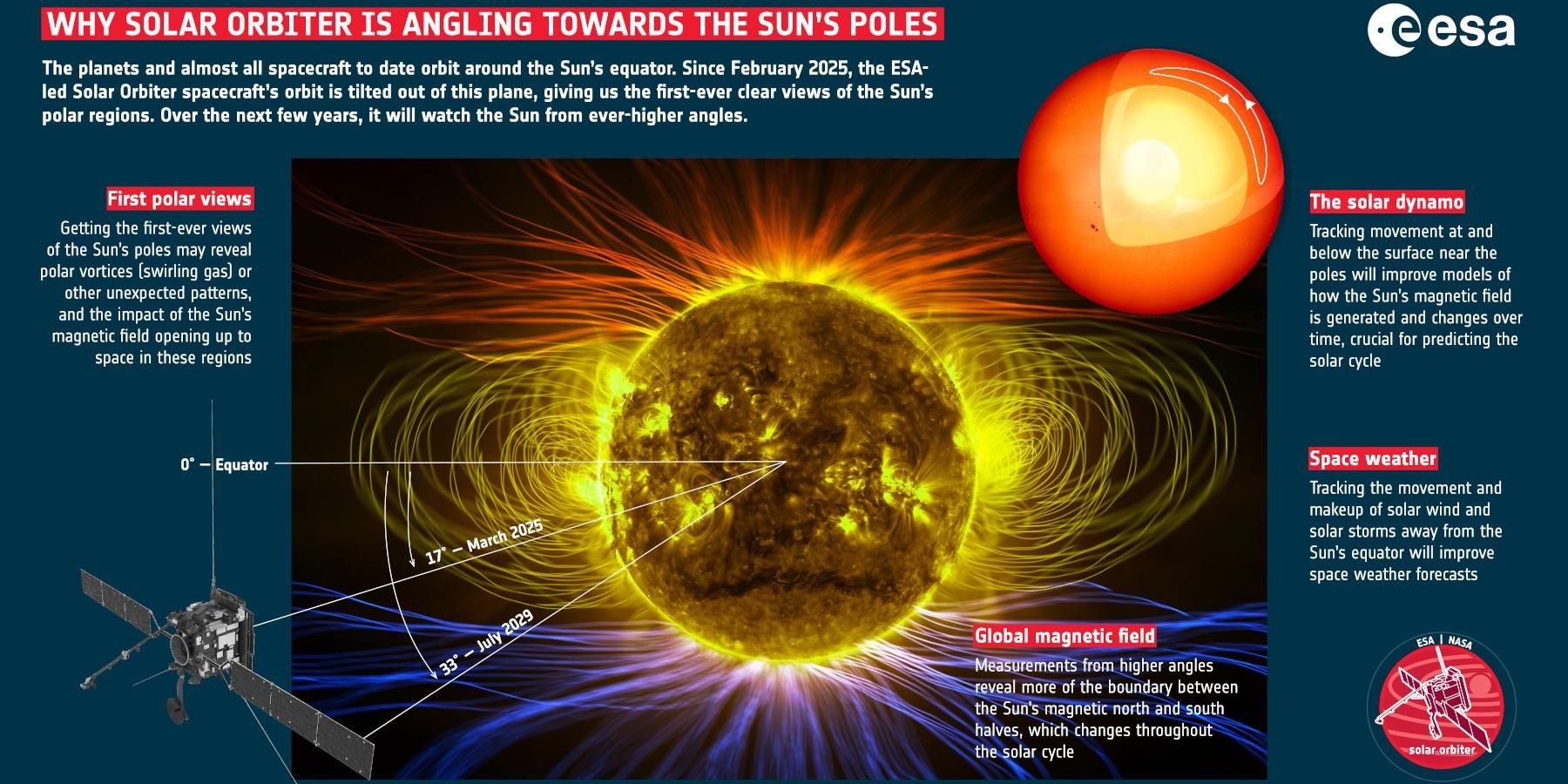

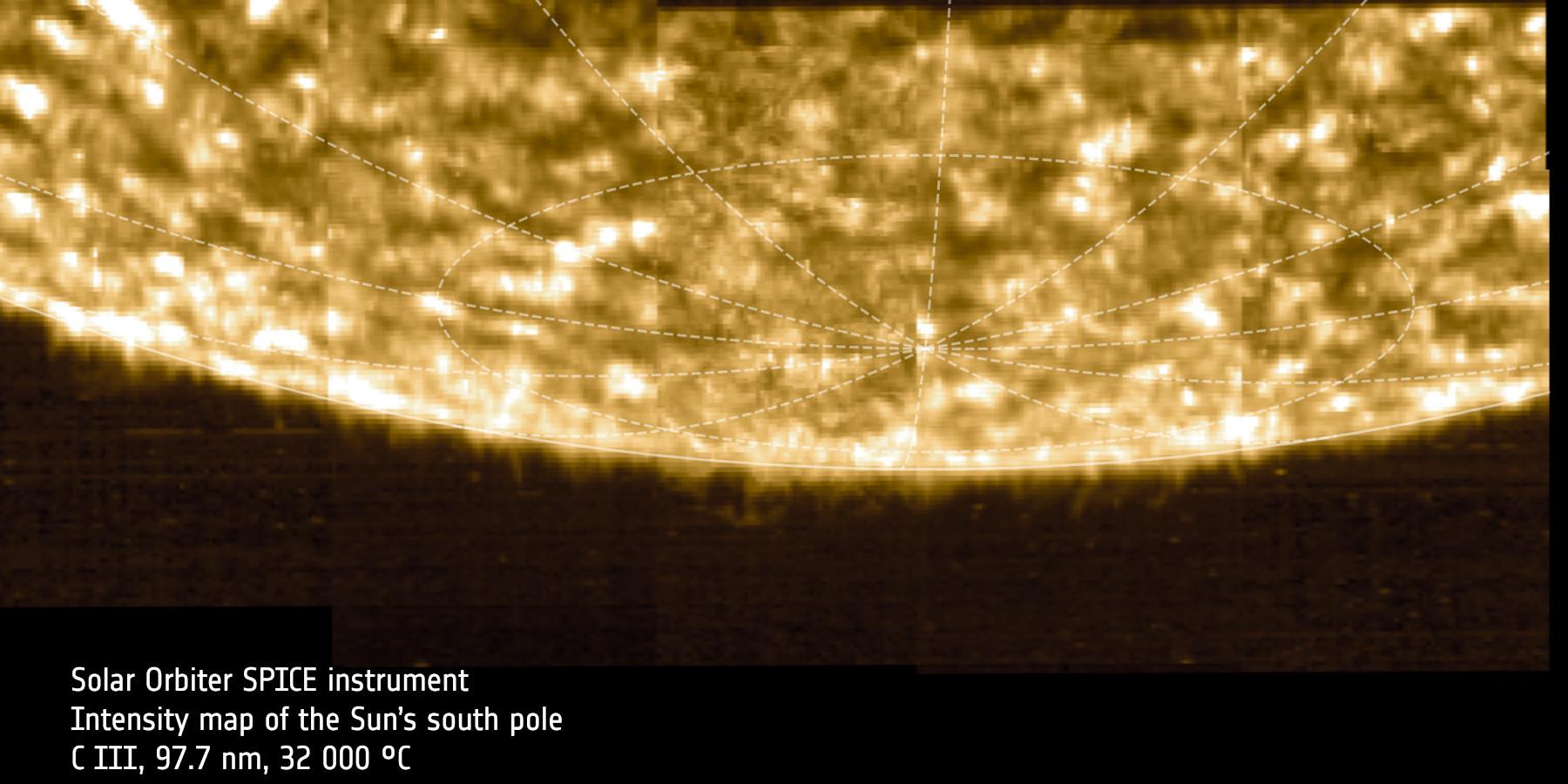

The Solar Orbiter mission of the European Space Agency (ESA) and NASA has captured the sharpest images to date of the Sun's south pole. This has been achieved thanks to silicon carbide photodiodes designed and manufactured by the Institute of Microelectronics of Barcelona (IMB-CNM-CSIC) in its Micro and Nanofabrication Clean Room, which are part of the spacecraft's photovoltaic panels. Located at an angle of 17º below the solar equator, the probe has been able to directly observe the south pole of our star. In the coming years, its orbit will be progressively tilted to offer even more detailed views and provide more information about the solar magnetic field and its evolution.

The probe's solar panels are protected by silicon carbide components manufactured in the Clean Room, a Unique Science and Technology Infrastructure (ICTS). These are 500 photodiodes essential to ensure the spacecraft's power supply and withstand the very high temperatures along its trajectory. Although the spacecraft can be exposed to more than 400 Celsius degrees, the orientation of the panels limits the temperature they receive directly to a maximum of 350.

These components are Schottky diodes developed by the Power Devices and Systems Group (PDS) of the IMB-CNM. They are made of silicon carbide, an advanced semiconductor with excellent properties for extreme environments: it withstands high electric fields, high current densities and high temperature.

"The solar panels are arranged in horizontal lines connected to each other. You have to keep everything working, even if one of them fails. Therefore, each of these lines of solar cells has a high-voltage diode (300 V, 5A) in series, an electronic component that makes it possible to disconnect the faulty line and ensure that the operation of the adjacent cells continues to be guaranteed," explains Miquel Vellvehi, principal investigator of the group.

The components were characterized and validated by the company ALTER Technology (ATN) for its use in space.

Electronic components from Barcelona to space

The components developed by IMB-CNM for the Solar Orbiter, with slight modifications in their parameters, are the same as those manufactured for other space missions, such as BepiColombo -the joint ESA-Japanese Space Agency (JAXA) mission to explore Mercury, launched in 2018- and Juice, the ESA probe launched in 2023 to study the moons of Jupiter.

Solar Orbiter is the most complex scientific laboratory ever sent to the Sun. It is the closest spacecraft to our star and the first to observe its polar regions. With its ten scientific instruments, the scientific community hopes to answer big unsolved questions: what drives the Sun's 11-year cycle of magnetic activity? What heats its corona, the upper layer of its atmosphere, to millions of degrees Celsius? How does the solar wind form and what accelerates it to speeds of hundreds of kilometers per second? And how does all this affect our planet?