CSIC manufactures microsensors to monitor fermentation and wine aging processes

The Institute of Microelectronics of Barcelona (IMB-CNM-CSIC) participates in a project to improve the monitoring of fermentation and aging of Catalan wine farms through sensors and chips. The sensorization of wineries seeks to improve the economic performance of farms and better cope with the effects of climate change in the coming decades.

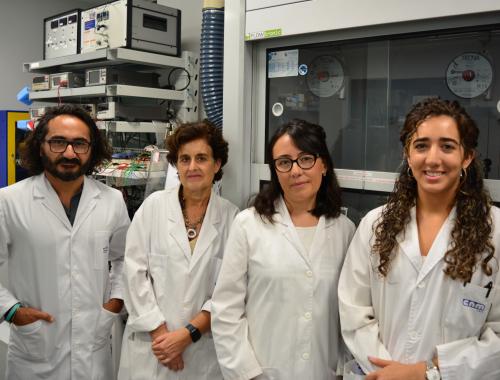

Main image: The project team at the IMB-CNM (from left to right): Murat Güneş, Cecilia Jiménez, Stella Vallejos and Yohana López. Image: Dani Ortega.

Developing low-cost tools for more reliable analysis, making more efficient use of energy and digitizing and modernizing the Catalan wine sector are some of the goals of the VISENS project. An initiative funded by the Generalitat de Catalunya in which the CSIC's Institute of Microelectronics of Barcelona (IMB-CNM-CSIC) is designing and manufacturing semiconductor-based sensors to improve fermentation and aging processes in this type of farming.

The IMB-CNM-CSIC is collaborating with the Clúster Vitivinícola Catalán (Catalan Wine Cluster, INNOVI), the wineries Celler La Vinyeta, Gramona and Vilarnau (González Byass) and the companies SC Robotics and Vega Instruments to incorporate new sensing devices in both tanks and barrels, integrate more efficient electronic systems and test their technical feasibility in an industrial environment.

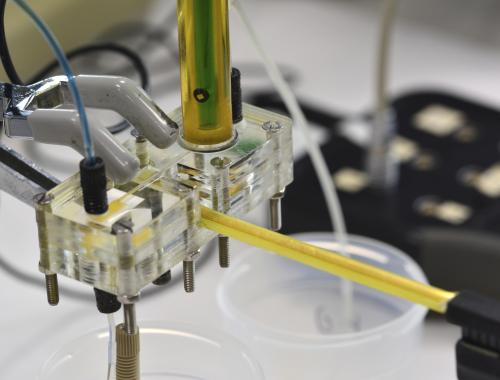

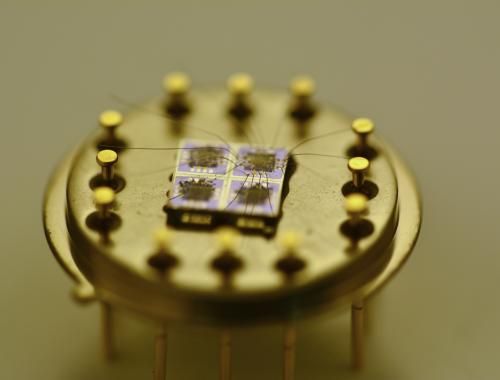

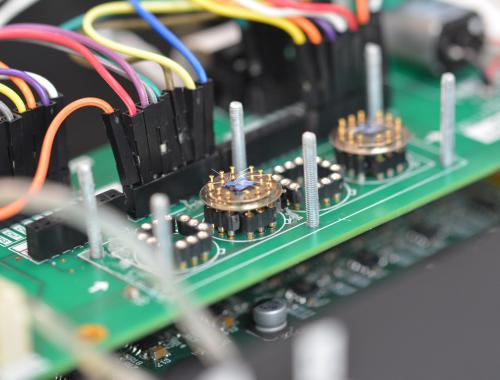

The IMB-CNM-CSIC devices are "electronic microsensors with microfluidic systems made on silicon that integrate other semiconductors that act as an active part in the detection of chemical species," explains Stella Vallejos, IMB-CNM researcher and leader of the scientific contribution to the project. "They are capable of measuring chemical compounds in vapor and liquid phase in real time," she adds.

The first tests to evaluate the performance of the sensors during wine aging will be carried out during this year’s harvest, while commercial devices were used last year. SC Robotics and Vega Instruments are providing commercial devices capable of measuring other parameters such as temperature, density and wine level during fermentation and/or aging.

Continuous monitoring to improve quality

"Continuous monitoring of fermentations makes it possible to standardize sampling, reduce human error and, above all, to detect when any deviation occurs and correct it in time," explains Víctor Tirado, from the INNOVI Cluster. Currently, fermentations are monitored once a day and the objective of the new sensors is to generate data every 15 minutes to ensure maximum product quality.

The implementation of sensorization options will reduce the costs of on-farm applications, increase efficiency and allow full control of the entire process.

"We are committed to the digitization of key processes in wine production with a range of solutions ranging from those already on the market to novel sensors that will reduce the use of additives such as sulfur," Tirado emphasizes.

The initiative requires constant exchange between the scientific and winemaking teams of the different wineries. The IMB-CNM involves two groups with different specialties, one in gas sensors and the other in sensors for liquids.

Adapting the sector to the challenges of the next 50 years

The project started at the beginning of 2022 and will continue until the end of 2024, although the first results are already being achieved. One of the main objectives is to modernize the technologies available to wineries so that they can meet the challenges that climate change will pose for the sector over the next half century, whether in terms of energy consumption, water availability or grape harvest analysis.

VISENS (“Pilot test of new generation sensor integration in Catalan wineries as a support method for decision making”) is a project funded through Operation 16.01.01 Cooperation for Innovation of the Rural Development Program of Catalonia 2014-2022 by the Department of Climate Action, Food and Rural Agenda of the Generalitat de Catalunya.

Image gallery

- The project team at the IMB-CNM (from left to right): Murat Güneş, Cecilia Jiménez, Stella Vallejos and Yohana López. Image: Dani Ortega.

- Liquid sensor developed for VISENS project. Image: Dani Ortega.

- VISENS sensor integration. Image: Dani Ortega.

- Integration of the VISENS sensor on a PCB board. Image: Dani Ortega.