Back to normal in the IMB-CNM Clean Room after the annual shutdown for maintenance and the arrival of new equipment

This unique location returns to full capacity today after an August in which most of the manufacturing processes were stopped in order to carry out the pertinent maintenance tasks at the facility. Normal activity is recovered with the incorporation of new equipment, such as the commissioning of the second new dichlorosilane cabin for the LPCVD (AFU) battery.

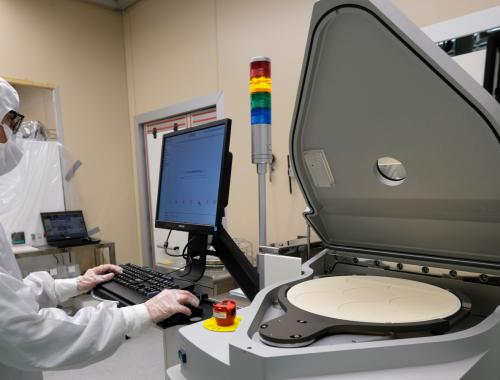

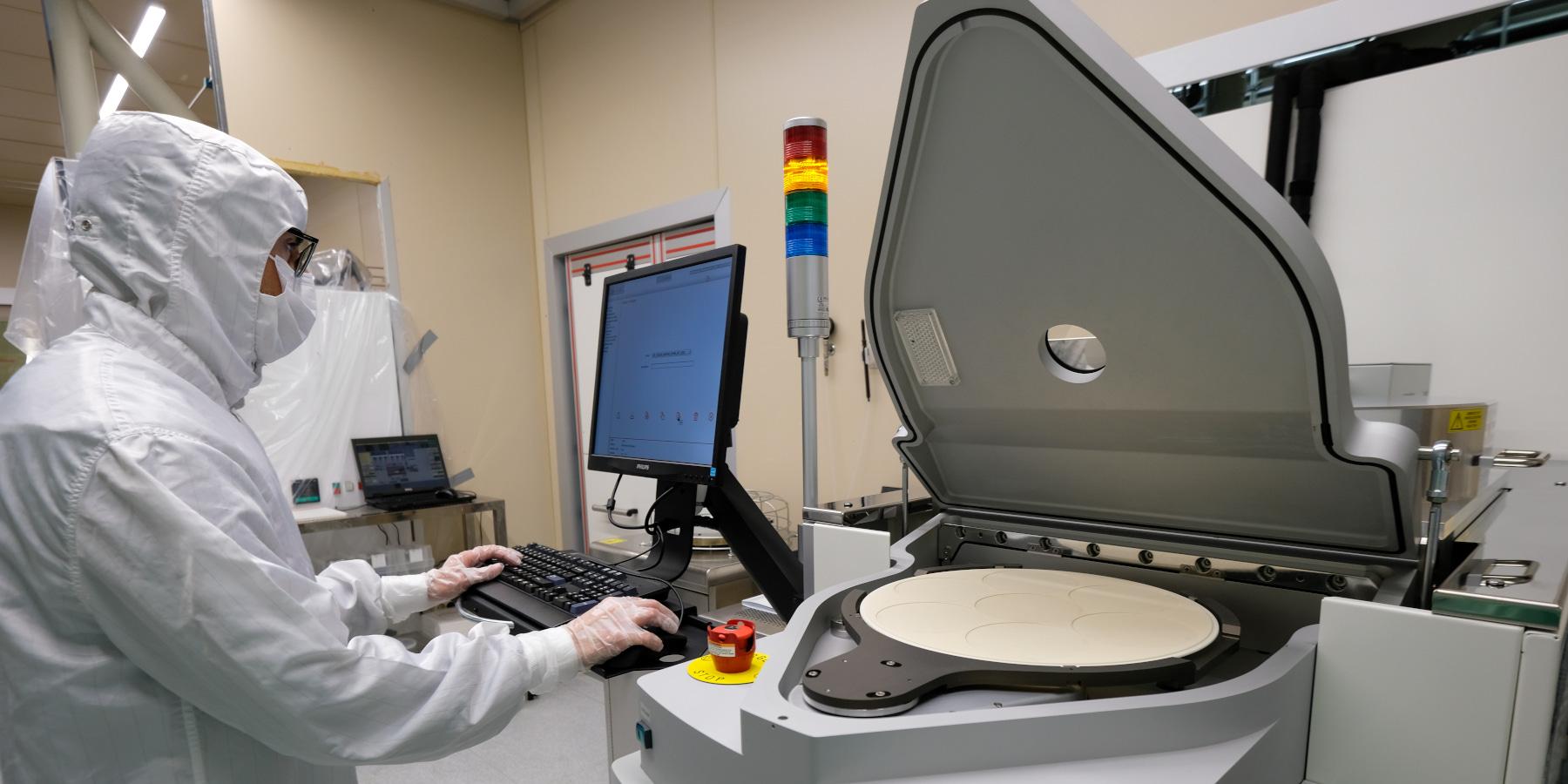

The Clean Room is a unique open access facility in southern Europe due to its characteristics, where it is possible to work on micro and nanometric scales to carry out research on silicon technologies and other semiconductor materials. The range of applications it covers is very wide, including biomedical applications, environment, food, energy and mobility, security, communications and consumer electronics.

An infrastructure of these characteristics requires regular maintenance to ensure proper operation of the facility throughout the year, which entails a total stoppage of the micro-manufacturing activity for several days. The management of the room schedules, together with the maintenance staff, a production interruption to check the operation of the service units and process equipment. It is a time where it is also used to install and fine-tune new equipment. The space, 1,500 square meters with about 170 active process equipment, goes through several phases until it recovers total production normality.

The IMB-CNM’s Micro and Nanofabrication Clean Room, recognized as a Unique Science and Technology Infrastructure (ICTS) by the Ministry of Science and Innovation, it is part of the current Spanish ICTS map made up of 29 structures that bring together a total of 62 facilities distributed throughout the national territory.

Maintenance work on installations and equipment

During the first week of August, the transformer station in the Clean Room was overhauled, as well as the maintenance and general review of the services of the entire facility.

Checking the transformer station forces the total cessation of activity and the closure of the centre for one day, since it requires a power cut. The maintenance team (where engineering, technical and maintenance personnel collaborate) also takes the opportunity to check the electrical subsystem and carry out renovations and improvements to its components. It is a common and periodic process in clean rooms of theses magnitudes.

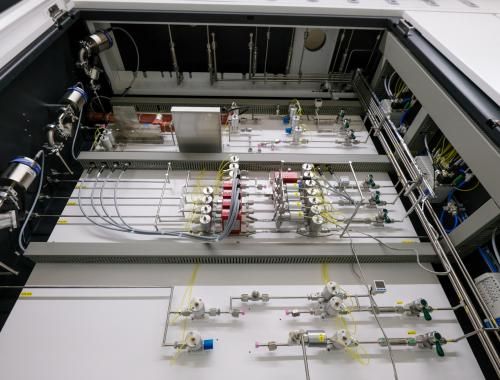

On the following days, preventive and corrective maintenance tasks are carried out on the services and facilities. The technical personnel in charge check the air conditioners in the different areas of the room and the cold production systems, the cooling water circuits, the process gas supply systems, the compressed air generation subsystems, the fire-fighting systems and the gas detector network, among others.

The maintenance of the process equipment is necessary to verify that everything works correctly, detect or resolve anomalies and deviations from the specifications (mechanical, optical, speed…). In this type of instruments, a deviation of less than 1 micron is already a deficiency. The shutdown is also used to renew components and subsystems. After the corrective actions, the equipment is restarted to have it operational on the production start date.

The cleaning of the equipment, spaces and work areas is also very important in the tasks scheduled for activity breaks, as it cannot be otherwise for a clean room. Some of the specific actions include: the cleaning of parts and maintenance areas of the equipment and process chambers, the cleaning and vacuuming of furnaces and their quartz tubes, the cleaning of auxiliary equipment (stoves, glove boxes, chillers, pumps…), the cleaning of the sample transport and handling utensils, the pickling of wafers and quartz pieces and the conditioning of filler wafers. These tasks usually last about three weeks.

New equipment co-financed with ERDF funds

The Clean Room facilities have new equipment already installed and in operation, thanks to the MINATEC-PLUS 1 (FICTS1420-02-18) project and MINATEC-PLUS 2 (FICTS2019-02-40) project, agreements signed between the Ministry of Science and Innovation and the CSIC for the application of European funds (ERDF) in the ICTS.

During the months of July and August, the second new dichlorosilane cabin for the CMOS (AFU) line LPCVD oven battery was put into operation and the first LPCVD nitride deposition processes –test- was carried out in the T10 AFU furnace. This technology will contribute to strengthening the integrated photonics line of the IMB-CNM.

Currently, work is being done to install a reflow soldering furnace for components and to modify the compressor cooling system.

Strategic asset for the deployment of the microelectronics and semiconductors Chip Strategic Project

The IMB-CNM and its Clean Room are considered a strategic asset in the State Chip Strategic Project for Economic Recovery and Transformation (PERTE Chip), as the main node of the Micronanofabs ICTS. The institute makes available to the Government its experience in the design and manufacture of electronic devices and systems, as well as its capacity to train students and professionals in these areas.

Last May, the Council of Ministers approved the PERTE Chip with the aim of comprehensively developing the chip design and manufacturing capabilities of the Spanish microelectronics and semiconductor industry. It is one of the most ambitious projects of the recovery plan with an amount of 12,250 million euros of public investment.

The first axis supposes the reinforcement of scientific capacity, the second refers to the design strategy, the third axis is oriented to the construction of manufacturing plants in Spain with a capacity both greater than, and less than, 5 nanometers and the fourth involves the revitalization of the European Information and Communication Technologies manufacturing industry.

The impact of the PERTE Chip will mean a transformation for the industry and a great contribution to the autonomy of Spain and the European Union in technological matters.