The IMB-CNM Clean Room is back to normal after the scheduled maintenance shutdown and the arrival of new equipment

The institute's large facility is back to full capacity after a month where production is stopped and maintenance tasks are carried out to prepare it for the rest of the year. Normal activity is resumed with new equipment, such as a new FIB, a new furnace battery or a new aligner.

The IMB-CNM's Micro and Nanofabrication Clean Room, recognized as a Unique Science and Technology Infrastructures (ICTS) by the Ministry of Science and Innovation, is recovering these days the normal operation of its units and equipment. The room's maintenance teams periodically stop production to check the operation of the services and equipment, as well as to install new instrumentation. The pause of all activity is necessary for the proper operation of the facility for the rest of the year.

The space, 1,500 square meters with about 170 active process equipment, goes through several phases until full normal production is restored at the research center. The Clean Room is a unique facility in southern Europe due to its characteristics, where it is possible to work at micro and nanometer scales to carry out research in silicon technologies and other semiconductor materials.

Overhaul of the transformer station

The first step is the shutdown and overhaul of the transformer station, which requires the total cessation of activity and the total closure of the center for one day. A total shutdown of the institute's power supply is required to carry out the various overhaul tasks and to take advantage of the opportunity to perform maintenance on the electrical subsystem, which cannot be carried out while the center is operating normally. This is a usual and periodic process in clean rooms of this magnitude.

"After the shutdown, the center's necessary services are restored and the opportunity is taken to replace the electrical elements that need updating," says Ana Sánchez Amores, head of continuous improvement at the ICTS.

The shutdown made possible to replace the general magneto-thermal circuit breaker in the old part of the building, which was necessary to shut off the power supply to the whole area, as well as changing the control and switching automatisms of the electrical network and the generator set in the new area of the Clean Room ("new area" is the name given to the 500 square meter extension carried out between 2007 and 2009).

Maintenance work on installations and equipment

During the week of total cessation of activity, the first of August, preventive and corrective maintenance tasks are carried out on the services and facilities. The personnel in charge check the air conditioning, cooling water circuits, process gas supply systems, compressed air generation subsystems, fire prevention systems and the gas detector network, among others. This year the filters of the air conditioners have also been changed and the belts and bearings have been checked and greased, among other things.

The maintenance of Clean Room process equipment is necessary to verify that everything is working properly, detect anomalies and resolve them. In this type of instruments, a deviation of less than 1 micron is already a deficiency. After the corrective actions, the equipment is restarted in order to have it operational on the production start date. The casuistry in the needs of the different equipment is large. Some cannot be shut down for a long time, as is the case for several nanolithography equipment (EBL, AURIGA or FIB), which must be started up and left on standby after shutdown in order not to lose the high vacuum of the electron accelerator columns.

Equipment cleaning also falls into the tasks scheduled for activity breaks. Some of the specific actions include cleaning and vacuuming of ovens, pickling of wafers and quartz parts, conditioning of screens with test processes and chlorine cleanings of quartz tubes. These tasks usually take about three weeks.

Division by each process area

The actions are distributed by area and the execution processes of each equipment are always tested after the performances. We also take the opportunity to test and develop recipes in new equipment, such as deposits of new materials in the Sputtering Kenosistec or silicon etching in the DRIE Sentech equipment.

New equipment co-financed with ERDF funds

The Clean Room facilities have new equipment already installed and in operation, thanks to the MINATEC-PLUS 1 and 2 projects, agreements signed between the Ministry of Science and Innovation and the CSIC for the application of European funds (ERDF) in the ICTS.

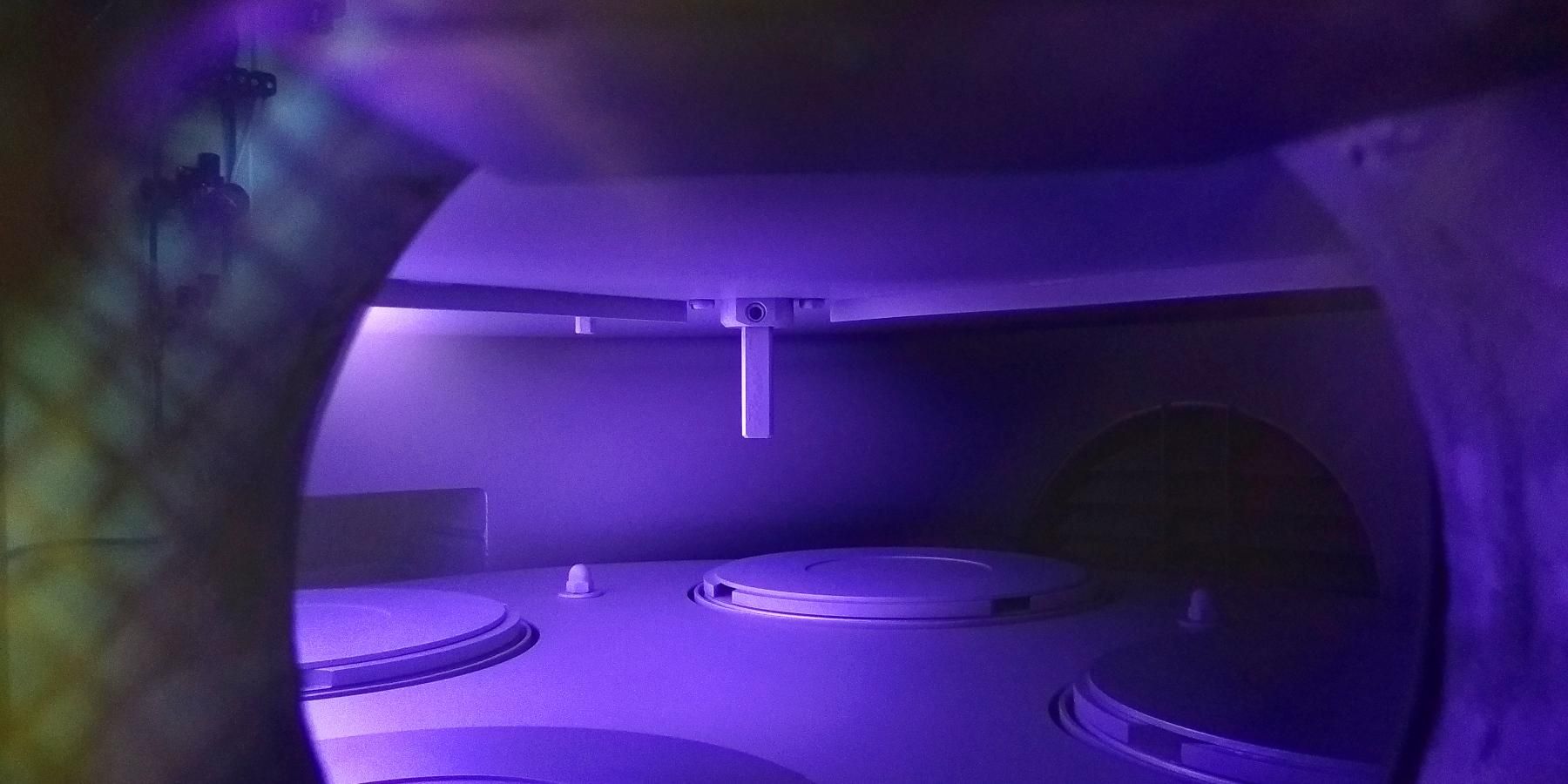

Some of them are almost fully operational, such as the AFK furnace battery of Tempress (a system with 4 horizontal tubes for thermal diffusion processes and LPCVD deposits) or the new automatic aligner of Suss (equipment for double-sided photolithography). Other equipment is in the process of installation, such as a dichlorosilane booth to service the AFK furnaces. The electrical installation, validation tests and commissioning have already been carried out, and work is currently underway on the commissioning of a new Zeiss FIB.

Preventive shutdown to continue research all year round

All the processes involved in the periodic shutdown of the production make it possible to schedule a full year of research in the Clean Room. The pause is necessary, as some tasks cannot be performed while the center is operating normally.

Starting this week, the IMB-CNM Clean Room will resume production and return to research.

More information

- The Clean Room of the National Microelectronics Centre is expanding its facilities with co-financing from ERDF funds.

- Technology offer of the Micro and Nanofabrication Clean Room.

Gallery

- 01: Sputtering KS800-HR-1 operating on the new target. Image: Eva Céspedes.

- 02: Furnace maintenance. Image: Ricard Noy.

- 03: Installation of the new FIB. Image: Albert Guerrero.

- 04: DCS Arcamo-Group Cabin. Image: Carles Mateu.

- 05: Technical staff working on the Univex 400. Image: Leyre Martínez.

- 06: Installation works on the Sputtering KS800-HR-1. Image: Eva Céspedes.