Equipment and processes of the Packaging Area

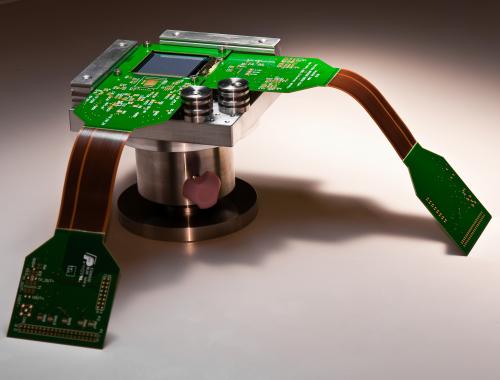

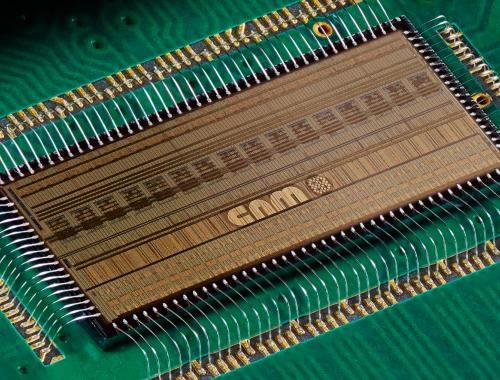

The Packaging area is the area in the Clean Room where tasks such as wafer dicing, die bonding or flip-chip are performed

Techniques

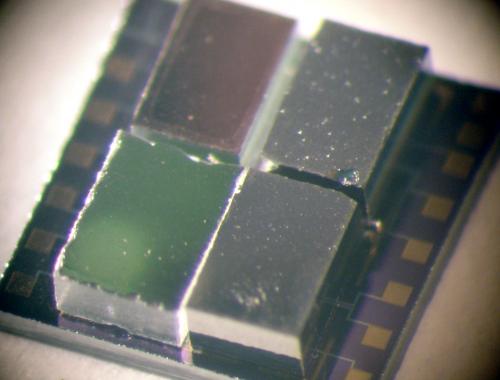

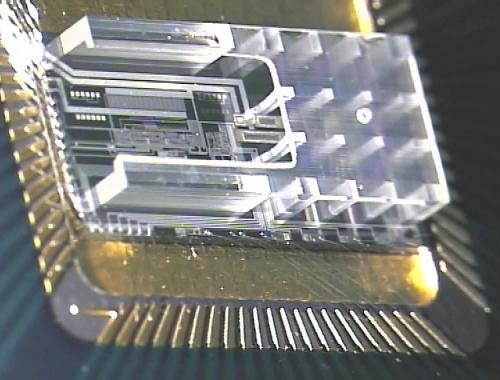

- Silicon wafers and different materials substrates dicing and cleaving

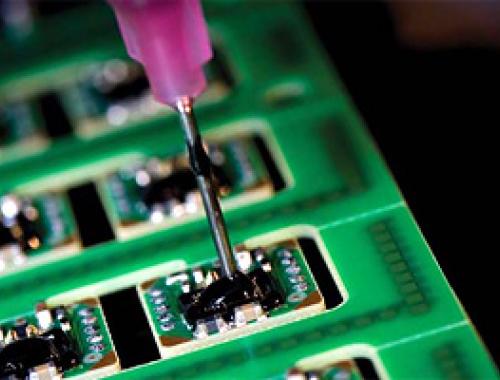

- Microelectronic devices Packaging: dispensing epoxy adhesives, wirebonding, ribbon bonding, Flip Chip, etc.

- Circuit Packaging test: destructive or non destructive test, wire bond shear test, die attach test by shear test, etc.

Equipment and Available capabilities

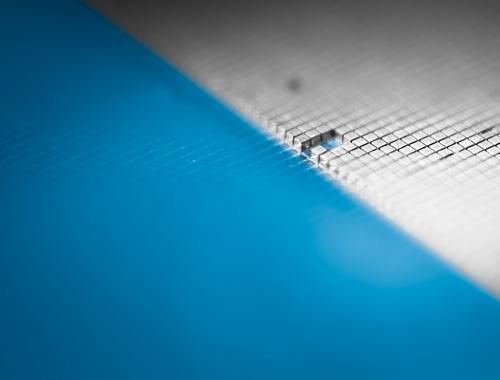

Substrate dicing

Semiautomatic Dicing machine K&S780

- Semi-automatic equipment

- Substrates up to 6”

- Y-axis accuracy: 2 µm

- Hub and hub less type 2" blades

- Multiple chip dimensions

- Multiple cutting depths

- Multiple rotation angles: Parametric

- Sawable substrate materials: Si, Ge, GaAs, GaN, Borosilicate, Al2O3, SiO2, SiC, LiNbO3

Dicing Machine K&S 980 (1998)

- Semi-automatic equipment

- Substrates up to 8"

- Y-axis accuracy: 2 µm

- Hub and hub less type 2" blades

- Multiple chip dimensions

- Multiple cutting depths

- Multiple rotation angles: By reference

- Sawable substrate materials: Si, Ge, GaAs, GaN, Borosilicate, Al2O3, SiO2, SiC, LiNbO3

Dicing Machine DISCO DAD-3350 (2019)

- Substrates up to 8"

- Circle cut for wafer downsizing

- US option for SiC

- In process checking

- CO2 Bubbler

- Additives for long-term processes

- Highly configurable and programmable with wizards and PRS

- Higher dicing quality with lower environmental impact

- Sawable substrate materials: Si, Ge, GaAs, GaN, Borosilicate, Al2O3, SiO2, SiC, LiNbO3

LatticeGear 420 Cleaver (2015)

- Cleaves almost all crystalline materials

- Clock dial for indent calibration

- Indent position control with 5 µm step size

- High accuracy positioning of sample (±10 µm)

- Resulting sample size down to 5 mm

- Polished tip diamond indenter with polished face for accurate positioning

- Colour CCD camera and Monocular, parfocal, zoom lens

- Up to 300 mm substrate size

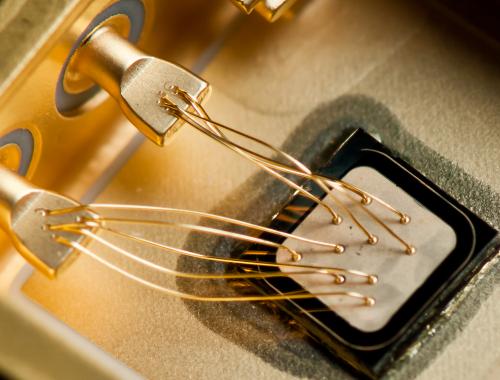

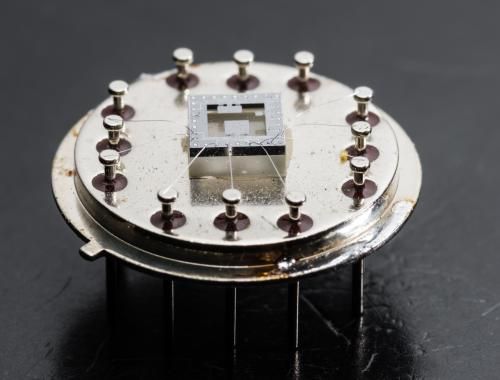

Microelectronic devices Packaging

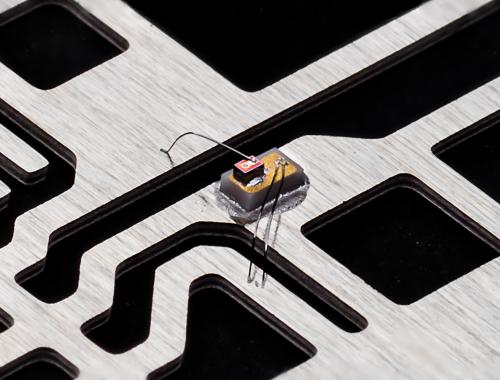

Dr. Tresky T4907 (2006)

- Manual Pick&Place

- Epoxy and soft paste dispenser

- Rework Station

- Flip chip option installed

- Placement accuracy: 10 µm

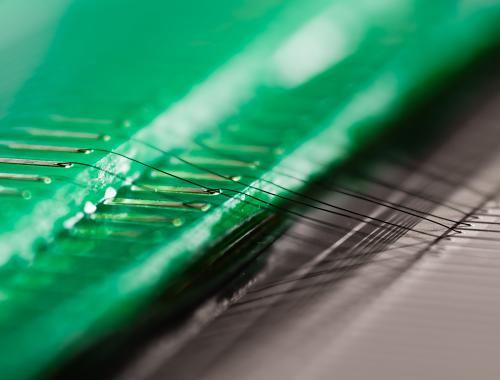

K&S 4123, 4523, 4127 Wedge Bonders (1986 y 2005)

- Fully manual bonders

- Accepts standard packages and substrates up to 4"

- Al, Au and Cu wires from 0.7 to 15 mils

- Heated sample holder

- Target light beam system

Wire Bonder TPT HB16 (2009)

- Semi auto, Deep Access wire and Ribbon Bonder

- Au, Al, Ag, Cu wire (17 to 75 µm) for Wedge & Ball Bonding

- Au and Al Ribbon up to 250 x 25 µm

- Large program storage capacity with more than 100 parameters

- Accepts flat packages and substrates up to 4"

- Heated sample holder

- Spotlight targeting system

- Possibility to make bumps for Flip-chip packaging

Bondtec 56XXi Wirebonder & Bond Tester (2022)

- Changeable bondheads for all wirebond and testing process

- Installed ball bonding (5610i) and Deep access wire bonding heads (5632i)

- Installed Pullheads - 100 cN - 5000 cN and Shearheads - 500 cN - 5000 cN

- Automatic bonding with pattern recognition system

- Adaptable bond settings (loop shapes, force and power profiles…), stored in unlimited bond programs

- Travel distances 100 mm x 100 mm

- Up to 1800 bonds/h

Royce 650 Die Shear & Bond Tester (2010)

- 305 mm x 155 mm stage for 300 mm wafers, leadframes or substrates

- Interchangeable test heads

- Die shear up to 200 kgf

- Wire Pull Test Force up to 10 kgf

- Total System Accuracy: ±0.1 %

Download the tecniques and capabilities of the Packaging Area

Packaging Team

- Alberto Moreno Garriga (ext. 435572)

- María Sánchez Martínez (ext. 435573)