Equipment and processes of the Inspection and Measurement Area

The Inspection and Measurement Area is the area in charge of two specific tasks: to verify that, after each process, the wafers are free of particles and defects and to characterize the deposited or etched layers by measuring different parameters (optical, electrical, mechanical, etc).

Techniques

- Optical Microscopy

- Spectral Reflectance

- Spectral Ellipsometry

- 3D optical Profilometry

- Mechanical Profilometry

- FT-IR Spectroscopy

- Sheet Resistance measurement

- Bow and Thickness measurement

- Life Time measurement

Equipment

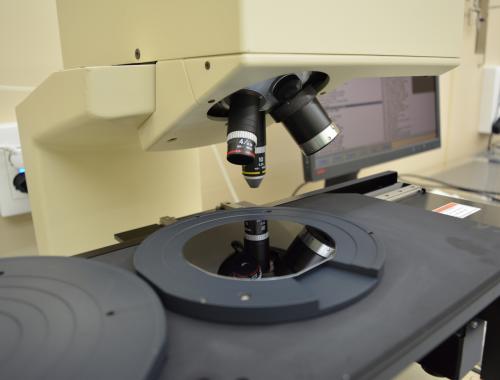

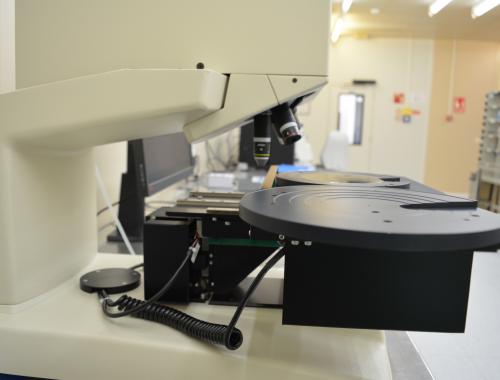

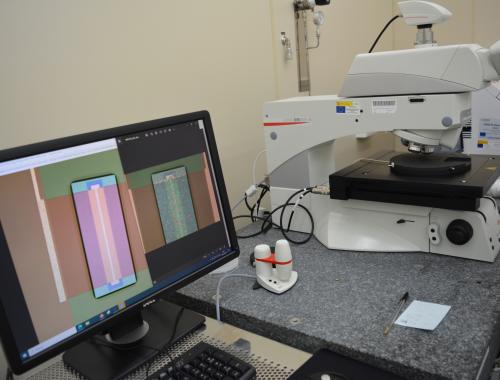

Optical Microscope: Leica DM8000

- Surface analysis: Defects and Particles

- Dimensions measurements

- Wafer-mapping

- Photomicrography

Spectral reflectometers: Nanospec 6100 and Nanospec II

- Thickness measurement of transparent layers

- Spectral Range: 440-1000 nm

- Predeterminated materials library

- New material analysis

- Multiple layer analysis

- Automatic XYZ stage

- Wafer mapping

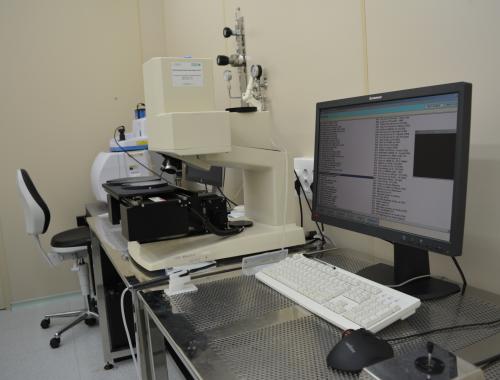

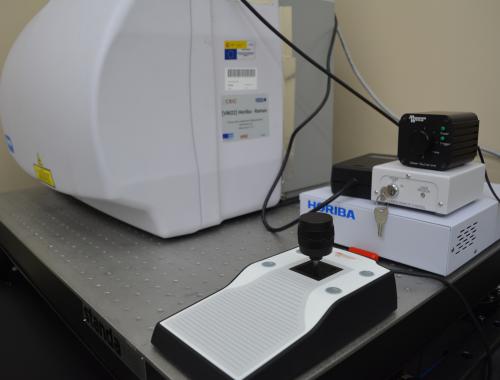

Spectral Ellipsometer: Horiba Auto SE

- Full analysis of thin films: thicknesses, optical constants, surface roughness, etc

- Automatic XYZ stage

- Real-time imaging

- Automatic selection of spot size

- Spectral range: 440-1000 nm

3D optical profilometer: Sensofar Neox

- Extract topographical data: surface morphology, step heights and surface roughness

- Fast data acquisition over large areas

- Noncontact and non-destructive measurements

- Large Z-axis range, feature heights from few nanometers up to 2cm

- Variable field of view

Mechanical Profilometers: Tencor P7 (x2, CMOS and MNC lines)

- Profile and roughness measurement in any type of sample (Transparent or Opaque)

- High accuracy in horizontal measurements: 1 um displacements

- Wide range in vertical measurements: 1 Å - 180 um

- Non-destructive technique for metals and semiconductors measurements

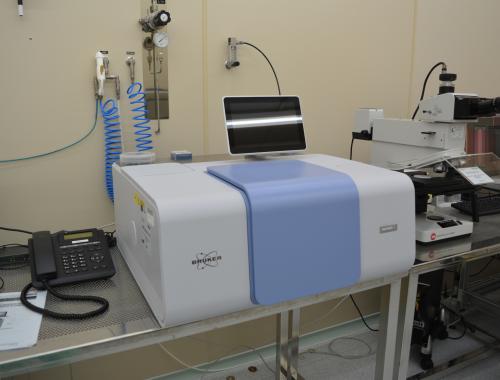

FT-IR Spectrometer: Bruker Invenio-S

- Qualitative and quantitative chemical analysis of layers (Si-O, Si-N…), dopants (P-O, B-O…) and impurities (NH, Si-H…).

- Spectral resolution: 8000-340 cm-1.

- Spectral resolution better than 0,4 cm-1

Four point probe Resistivity Measurement: Chang Min Four (x2, CMOS and MNC lines)

- Resistivity measurement of thin layers of conductive and semiconductor materials

- Characterization of uniformity in the metal deposit, polysilicon doping and ion implantation

Geometrical characterization: Proforma 300

- Bow and Total Thickness capacitive measurement

- One-point non-contact

Tencor Sonogage RT2

- Resistivity and wafer Thickness measurement

- Wafer thickness measurement

- Bulk resistivity characterization

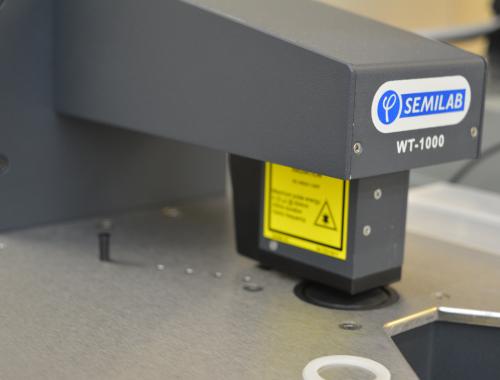

Carrier lifetime Measurement: Semilab WT-1000

- Incoming wafer characterization

- Measurement of electrical parameters in different manufacturing steps

- Characterization of deposited layer parameters

Available capabilities

- Surface and particle analysis.

- Thickness measurement of transparent layers using optical techniques: SiO2, Si3N4, Al2O3, PolySi, HfO2, etc.

- Analysis of the optical characteristics of materials.

- Mechanical profilometry of surfaces and study of the roughness of substrates and deposited layers.

- FT-IR spectroscopy of materials deposited on wafers.

- Measurement of the resistivity of substrates, metals and doped semiconductors.

- Wafer thickness and curvature measurement.

- Lifetime measurement of minority carriers.

Download the techniques and capabilities of the Inspection and Measurement Area

Check the Inspection and Measurement Area

Inspection and Measurement Team

- Samuel Dacunha Pazos (ext. 435571)