Equipment and processes of the Microsystems Area

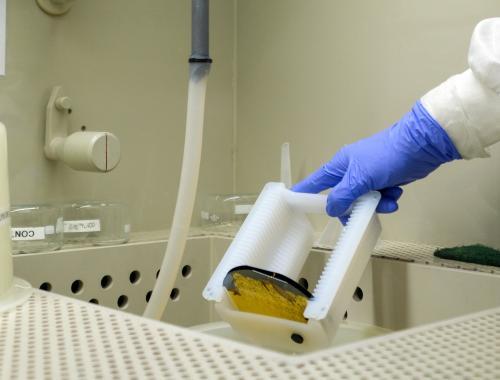

The Microsystems Area is the area where wet etching, lift-off processes, metal deposition and wafer bonding are performed.

Techniques

- Wet etching

- Lift-off process

- Metal deposition

- Wafers bonding

Equipment

Wet etching and cleaning:

- 2 Chemical benches one for CMOS compatible wafers and another for wafers with contaminant metals.

- 4 heated baths for anisotropic wet etching of silicon in alkaline solutions.

- 4 multipurpose baths for metal etching and chemical depositions of metals.

- 4 overflow rinse tanks for wafer cleaning and 2 nitrogen guns for wafer drying.

Lift-off:

- 3 ultrasonic baths.

- Gas cabinet.

Metal deposition:

- 2 baths for the chemical deposition of metals by Electroless.

- Gas cabinet for electroplating processes.

- Autolab to control the electrochemical processes.

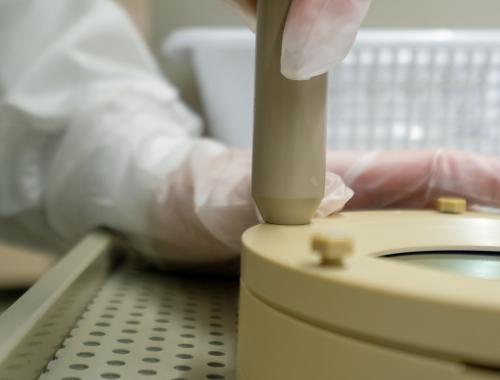

Critical point dryer of CO2:

- Automegasandri 915 B@Tousimis.

Anodic bonding:

- Suss Microtech Sb6e.

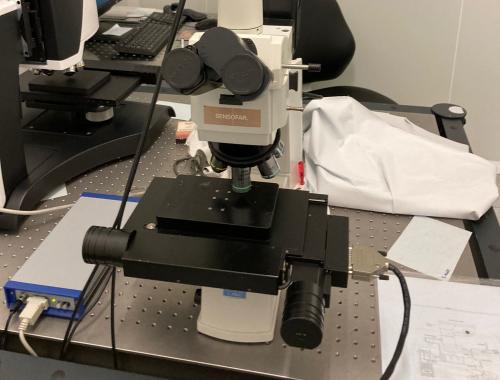

Test equipments:

- Optical microscope.

- Stereoscope microscope.

- 3D optical profiler.

Available capabilities

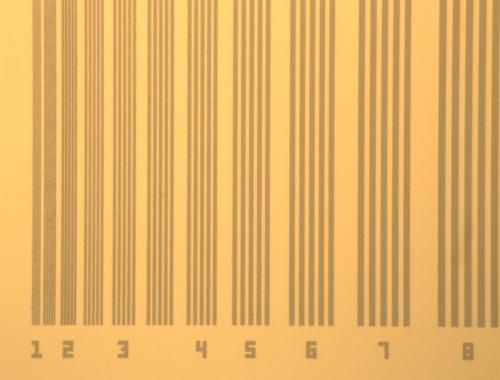

Anisotropic wet etching of Silicon for bulk micromachining in alkaline solutions

KOH is used as etching solutions. SiO2 and Si3N4 are used as mask layers during the etching. Three different etch-stop methods are available:

- Time

- High selectivity layers

- Highly doped zones

Surface micromachining of silicon

Polysilicon is used as structural layer meanwhile the silicon oxide acts as sacrificial layer. HF-based solutions are used as etchants for the sacrificial layer etching. The process can be also done by HF-vapors. After the etching the samples can be dried by critical point dryer of CO2 to avoid the sticking of the released structures.

Lift-off process

Patterning of metallic layers without chemical etching of the layer. The process can be performed for metals deposited by evaporation or, even by, sputtering.

Chemical deposition of metals by Electroless

Processes that create metal coatings on various materials surfaces by autocatalytic chemical reduction of metal cations in a liquid bath. Available metals are nickel, gold and copper.

Electrodeposition of metals by electroplating

Processes that create a metal coating on a solid substrate through the reduction of cations of that metal by means of a direct electric current. Available metals are nickel, gold, and copper.

Wet etching of metal

Wet etching of chrome, aluminium, titanium, nickel, gold, tungsten.

Wafers bonding

- Anodic bonding (silicion-glass)

- Eutectic bonding (silicon-gold)

Download the tecniques and capabilities of the Microsystems Area

Check the Microsystems Area

Microsystems Team

- Marta Duch (ext. 435566)

- Evelyn Castro (ext. 435687)

- Laia Forner (ext. 435545)