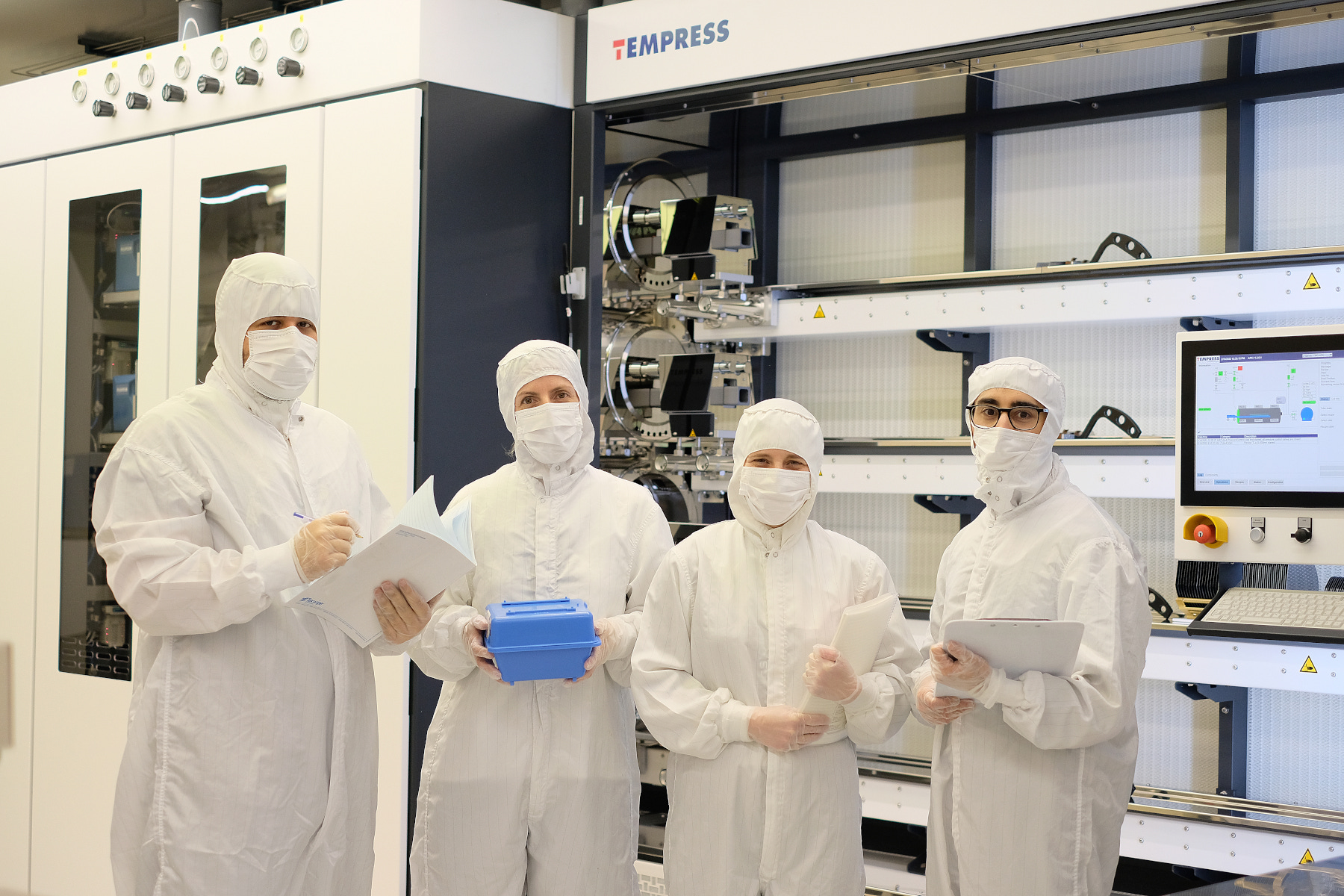

Equipment and processes of the Thermal Processes Area

The Thermal Processes Area is a main space where critical techniques in micro and nanofabrication are performed, such as Thermal silicon oxidation, Low pressure chemical vapor deposition (LPCVD) or Plasma-enhanced chemical vapor deposition (PECVD).

Techniques

- Thermal silicon oxidation

- Diffusion and annealing processes

- Rapid thermal processing (RTP)

- Low pressure chemical vapor deposition (LPCVD)

- Plasma-enhanced chemical vapor deposition (PECVD)

- Atomic layer deposition (ALD, PEALD)

Equipment

Thermal silicon oxidation, diffusion and annealing processes and low-pressure chemical vapor deposition (LPCVD)

4 racks of 4 horizontal tubular furnaces each. 15 furnaces are allowed to process CMOS (clean) samples, and 1 is dedicated to MNC processing (metal contaminated samples). Wafers up to 150 mm diameter or below.

- Brand: Tempress, Model: TS-Series V

- Furnace: AFS

- Brand: Tempress, Model: TS-Series V

- Furnace: AFT

- Brand: Tempress, Model: TS-Series V

- Furnace: AFU

- Brand: Tempress, Model: TS-Series V

- Furnace: AFK

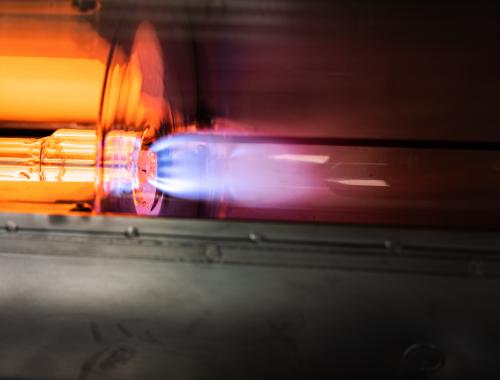

Rapid thermal processing (RTP)

- Annealsys, AS-Master-2000: 1 chamber. CMOS processing (clean samples). Wafers up to 200 mm diameter or below.

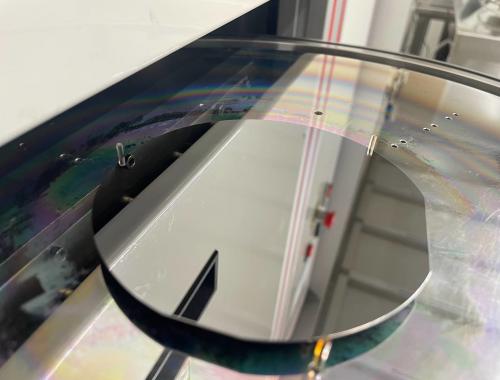

Plasma-enhanced chemical vapor deposition (PECVD)

- Applied Materials, Precision 5000 Mark II: 1 tool with 3 chambers. CMOS processing (clean samples). Wafers up to 150 mm diameter.

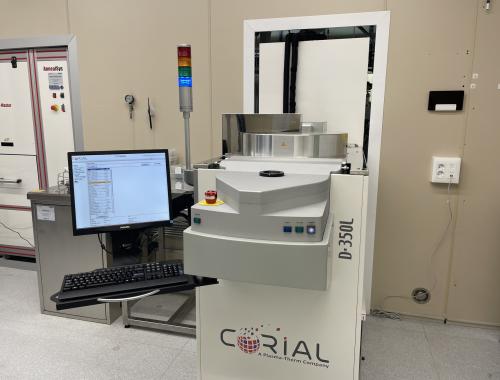

- Corial, D350L: 1 chamber. CMOS (clean samples). Wafers up to 150 mm diameter.

- Oxford IPT, Plasmalab 800 Plus: 1 chamber. MNC processing (metal contaminated samples). Wafers up to 200 mm diameter

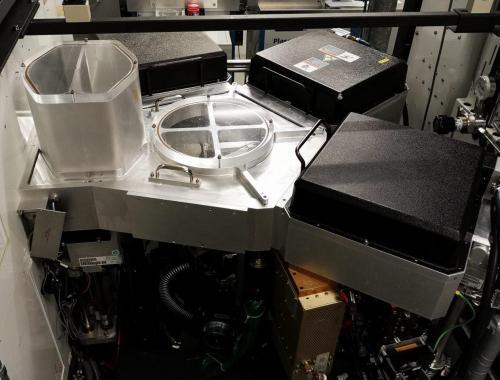

Atomic layer deposition (ALD, PEALD)

- Thermal: Cambridge Nanotech, Savannah 200: 1 chamber. CMOS processing (clean samples). Wafers up to 200 mm diameter.

- Thermal and plasma enhanced: Picosun, R200 Advanced: 1 chamber. MNC processing (metal contaminated samples). Wafers up to 200 mm diameter.

Available capabilities

Thermal silicon oxidation

- Temperature range from 900ºC to 1100ºC

- H2 & O2 or H2O with C2H2Cl2 environment

- Thickness range from 5 nm up to 3000 nm

- In-wafer and wafer to wafer uniformity below 1%

- Batch capacity 50 wafers

Diffusion and annealing processes

- Annealing in N2, O2, N2O or Ar environment from 600ºC to 1300ºC

- Aluminum annealing in N2/H2 environment from 250ºC to 450ºC

- MNC thermal annealing from 600ºC to 1100ºC

- Phosphorus pre-deposition (Liquid source, POCl3)

- Boron pre-deposition (Liquid source, BBr3)

- Batch capacity 50 wafers

Rapid thermal processing (RTP)

- Rapid thermal annealing (RTA) available under O2, N2, N2O and Ar environment from 400ºC to 1200ºC

- Rapid thermal oxidation (RTO) available under O2 environment from 400ºC to 1200ºC

- Single wafer system

Low pressure chemical vapor deposition (LPCVD)

- Silicon nitride (Si3N4) deposition at 800ºC for thicknesses from 10 nm to 300 nm

- Low stress silicon nitride (Si3N4) deposition at 850ºC for thicknesses from 10 nm to 300 nm

- Polysilicon (PolySi) deposition at 630ºC for thicknesses from 30 nm to 3 μm

- Amorphous silicon (a-Si) at 565ºC for thicknesses from 30 nm to 3 μm

- Silicon oxide (SiO2) at 700ºC for thicknesses from 50 nm to 300 nm

- In-wafer and wafer to wafer uniformity below 3%

- High quality films and good step coverage

- Batch capacity 25 wafers

Plasma-enhanced chemical vapor deposition (PECVD)

Applied Materials – Precision 5000 mark II

- Automatic single wafer multi-chamber system with cassette

- Silicon oxide (SiO2) deposition at 400ºC for thicknesses from 50 nm to 5 μm

- Two silicon precursors available: Tetraethyl orthosilicate (TEOS) and Silane (SiH4)

- Silicon nitride (Si3N4) deposition at 400ºC for thicknesses from to 50 nm to 1 μm

- Passivation layer: Silicon oxide (SiO2) combined with Silicon nitride (Si3N4) at 375ºC as diffusion barrier and against-moisture layer

- In-wafer and wafer to wafer uniformity below 10%

- Batch capacity 15 wafers

Corial – D350L

- Silicon oxide (SiO2) deposition up to 320ºC for thicknesses from 50 nm to 5 μm

- Two silicon precursors available: Tetraethyl orthosilicate (TEOS) and Silane (SiH4)

- Silicon nitride (Si3N4) deposition up to 320ºC for thicknesses from to 50 nm to 1 μm

- Amorphous silicon deposition (a-Si:H) at 200ºC for thicknesses from 50 nm to 500 nm

- Deposition of doped silicon oxide (with Boron and/or Phosphorous) at 320ºC to form BSG (borosilicate glass), PSG (phosphosilicate glass) or BPSG (borophosphosilicate glass) for planarization capabilities, and thicknesses between 1 μm – 2 μm

- In-wafer and wafer to wafer uniformity below 10%

- Batch capacity of 7 wafers of 100 mm or 1 wafer of 150 mm

Oxford IPT - Plasmalab 800 Plus

- Silicon oxide (SiO2) deposition (SiH4) at temperatures up to 380ºC for thicknesses from 50 nm to 5 μm

- Silicon nitride (Si3N4) deposition at temperatures up to 380ºC for thicknesses from 50 nm to 1 μm

- Amorphous silicon (a-Si:H) deposition up to 300ºC for thicknesses from 50 nm to 1 μm

- Dual frequency plasma available (13.56 MHz/350 kHz) for low stress silicon oxide and silicon nitride layers

- In-wafer and wafer to wafer uniformity between 10%

- Batch capacity of 8 wafers of 100 mm, 4 wafers of 150 mm or 1 wafer of 200 mm

Atomic layer deposition (ALD)

Cambridge Nanotech - Savannah 200

- Temperature range: from 150ºC to 350ºC

- Thicknesses from 0.5 nm to 50 nm

- Aluminum oxide (Al2O3)

- Hafnium oxide (HfO2)

- Titanium oxide (TiO2)

- Nanolaminates

- 2 types of oxidant precursors: D. I. H2O and O3

- In-wafer thickness uniformity around 1-2%

- Batch capacity of 2 wafers of 100 mm, 1 wafer of 150 mm or 1 wafer of 200 mm

Picosun - R200 Advanced

- Temperature range: from 60ºC to 300ºC

- Thicknesses from 0.5 nm to 50 nm

- Aluminum oxide (Al2O3), thermal and plasma enhanced

- Hafnium oxide (HfO2), thermal and plasma enhanced

- Titanium oxide (TiO2), thermal

- Silicon oxide (SiO2), plasma enhanced

- Nanolaminates

- Sequential infiltration synthesis (SIS)

- 2 types of oxidant precursors: D. I. H2O and P. E. O2

- In-wafer thickness uniformity around 1-2%

- Single wafer system

Download the tecniques and capabilities of the Thermal Processes Area

Thermal Processes Team

- Sara Durán (ext. 435561)

- Ricard Noy (ext. 435554)

- Elena Chica (ext. 435580)

- Olaf Vázquez (ext. 435688)