Equipment and processes of the Metallization Area

The Metallization Area is the area where metal thin films of a variety of materials can be deposited by Physical Vapour Deposition techniques on either DC and DC/RF sputtering systems, or on thermal and e-beam evaporation systems.

Techniques

- Physical Vapor Deposition on Sputtering Systems (DC and DC/RF)

- Physical Vapor Deposition on Evaporation and E-Beam Systems

Equipment and Available capabilities

Physical Vapor Deposition on Sputtering Systems

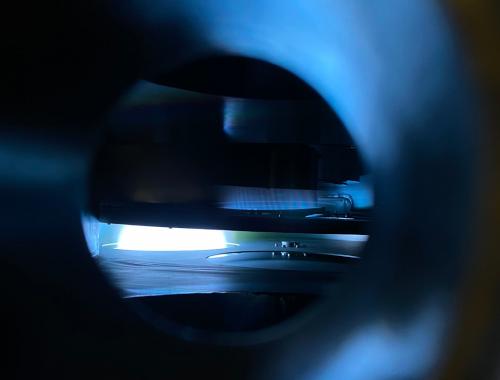

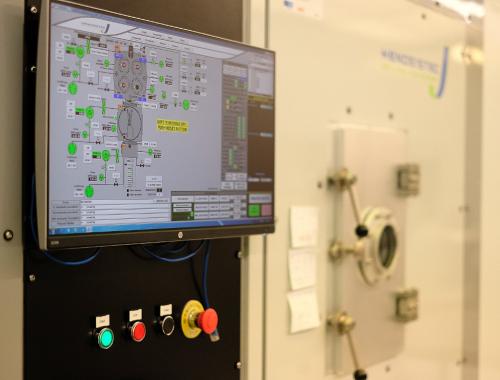

KENOSISTEC KS800H:

- Sputtering system to deposit metallic layers on 100 mm or 150 mm wafers.

- Process chamber with three (200 mm) circular planar magnetron cathodes.

- Available targets: Al99.5/Cu0.5, Ti and Cu.

- Load lock chamber with semi-automatic loading system.

- DC power and RF for sputter etching.

- Possibility to process CMOS or no-CMOS wafers (no-CMOS without etching).

Material Research Corporation-MRC 903:

- Sputtering system to deposit metallic layers on a 30 x 30 cm2 pallet surface (up to nine 100 mm wafers or up to four 150 mm wafers).

- Process chamber with three cathodes (two are rectangular planar magnetron-type and the other is a rectangular planar diode).

- Available targets: Au, Ni and Ti.

- Load lock chamber with semi-automatic loading system.

- DC power for Ti/Ni and RF power for Au. Also RF for sputter etching.

- Aimed at no-CMOS wafers.

KENOSISTEC KS500C:

- Sputtering system to deposit metallic and semiconducting layers on 100 mm or 150mm wafers.

- Process chamber with three cathodes (75 mm) magnetron circular planar in confocal configuration.

- Available targets: W, Ti, Ta, Si and TaSi2

- Load lock chamber with semi-automatic loading system.

- DC power supply source plus RF power supply for one cathode (to deposit Si). Possibility to sputter etching (RF).

- Possibility to process CMOS and no-CMOS wafers (no-CMOS without etching).

LEYBOLD HERAEUS Z-550:

- Sputtering system to deposit metallic layers on 100 mm wafers.

- Process chamber with a circular planar magnetron cathode.

- Available targets: Al, Al98.75/ Cu0.5 /Si0.75 and TaSi2.

- Load lock chamber and manual loading system.

- DC power supply source. Possibility to sputter etching (RF).

- Possibility to process CMOS or no-CMOS wafers (no-CMOS without etching).

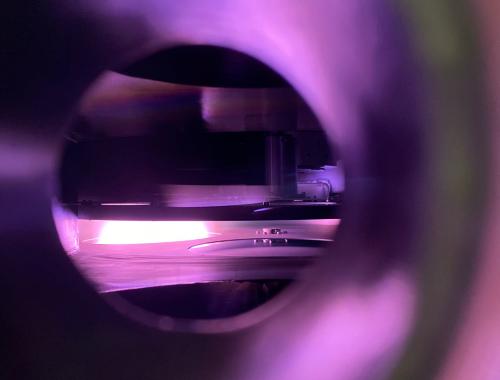

KENOSISTEC KS800HR:

- Sputtering system to deposit metallic and non-metallic layers on 100 mm, 150 mm wafers.

- Process chamber with four (200 mm) circular planar magnetron cathodes.

- Available targets: Al, Al99.5/Cu0.5, Ti, W, Si, AlN, TiN, Si3N4, SiO2

- Load lock chamber with semi-automatic loading system.

- Possibility to heat samples up to 400 ºC

- Pulsed DC and RF power supply sources, plus RF for sputter etching.

- To process no-CMOS samples

BIO RAD E-5000 Polar Division:

- Sputtering system to deposit gold layers for scanning electron microscopy.

- Possibility to change distance and current.

- Stopwatch to time control.

Physical Vapor Deposition on Evaporation and E-Beam Systems

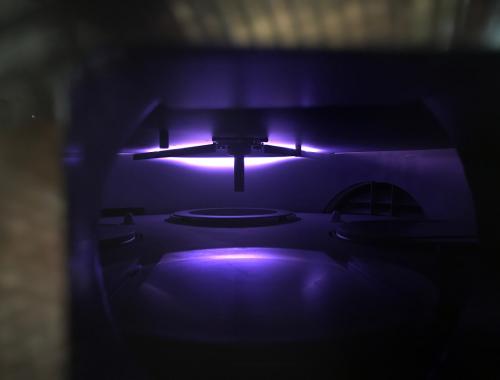

OERLIKON UNIVEX 450B:

- One electron gun source with four pockets and two thermal sources.

- Maximum sample area size: 150 mm.

- Process chamber capacity up to four wafers (Manual loading system without load lock chamber)

- Available materials: Ag, Al, Al2O3, Au, B, C, Cr, Cu, Fe, ITO, Mo, Nb, Ni, Pd, Pt, Sn, Ta, Ti, W, ZnO and Zr.

- Possibility to heat samples up to 500ºC.

- Residual gas Analyzer.

- Available deposition in low O2 pressure.

- To process no-CMOS samples.

KENOSISTEC KE500E:

- One electron gun source with four pockets.

- Maximum sample area size: 150 mm.

- Process chamber capacity limited to one wafer (manual loading system without load lock chamber).

- Available materials: Al, Cr, Ti.

- Exclusively to process CMOS samples.

LEYBOLD UNIVEX 400:

- One electron gun source with eight pockets

- One i-gun source.

- Maximum sample area size: 150 mm.

- Process chamber capacity of one wafer with load lock chamber.

- Possibility to cool samples between -20 and 100 ºC.

- Possibility to sample rotation during deposition

- Available materials: In test: (Ti, Au, Al)

- To process no-CMOS samples.

Download the tecniques and capabilities of the Metallization Area

Check the Metallization Area

Metallization Team

- Leyre Martínez de Olcoz Sainz (ext. 435563)

- Josep Montserrat i Martí (ext. 435553)

- Marc Isart Alemany (ext. 435690)