Equipment and processes of the Dry Etching Area

The Dry Etching Area is the area where plasma etching techniques are carried out on different materials used in microfabrication.

Techniques

- Metal etching

- Semiconductors

- Polymers

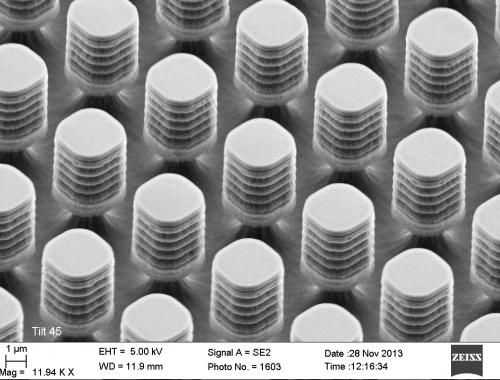

- Deep silicon etching with HAR

- Etching for silicon nanostructures

Equipment and Available capabilities

Alcatel 601 E

- Automatic single-wafer up to 100 mm

- ICP Gen. up to 2000 W - 13,56 MHz

- RF Gen. up to 500 W - 300 KHz

- Gas lines: SF6, C4F8, He, O2

- 2 mechanical pumps 2 turbomolecular pumps

- Wafers thermalization: -110°C to 40°C (N2 dewar); He-backside contact

- Bosch process

- Layer etching: Silicon, polysilicon, W and TaSi

OXFORD PLASMALAB S-100 no CMOS

- Automatic multiwafer up to 100 mm. Two chambers

- ICP Gen. to 5000 W-2 MHz and ICP Gen. up to 3000 W-13.56 MHz

- RF Gen. up to 600 W-13,56 MHz

- Gas lines: N2, O2, He, SF6, Cl2,.

- Chamber 1: HBr, BCl3, Cl2, SF6, N2, He, Ar

- Chamber 2: SF6, O2

- 3 mechanical pump 2 turbomolecular pump

- Wafers thermalization: 20°C to 60°C; He-backside contact

- Layer etching: Group III-V compound semiconductors, SiC, diamond and photoresist stripping

Aplied Materials P5000

- Industrial platform 3 chambers up to 150 mm

- Magnetic field assisted, up to 90G – MERIE

- 3 RF Gen. up to 1250 W - 13,56 MHz

- 3 mechanical pumps 3 turbomolecular pumps

- Gas lines:

- Chamber A: CF4, C2F6, He, CHF3, Ar

- Chamber B: C4F8, CF4, C2F6, O2, He, CHF3, Ar

- Chamber C: HBr, Cl2, CF4, He/O2, SF6, N2

- Layer etching: Polysilicon, SiO2, Si3N4

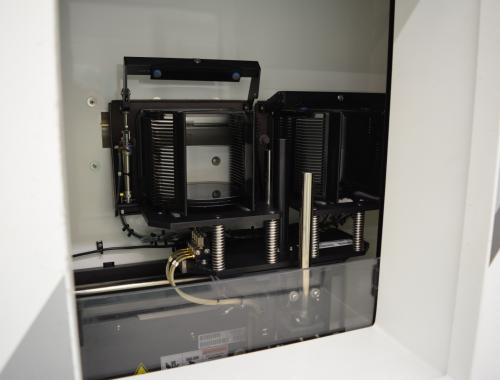

Alcatel AMS-110 DE no CMOS

- Automatic single-wafer up to 100 mm

- ICP Gen. up to 3000 W - 13,56 MHz

- RF Gen. up to 600 W - 300 KHz

- RF Gen. Up to 500 W LF

- Gas lines: SF6, C4F8, He, O2 CH4, Ar

- 1 mechanical pumps 1 turbomolecular pumps

- Wafers thermalization: -10°C to 420°C; He-backside contact

- Bosch process

- Layer etching: Silicon, polysilicon, W, TaSi, SiO2, Si3N4, Al2O3, HfO2, TiO2, GaO, pyrex, polyimide, Graphene

SENTECH SI 500 No CMOS

- Automatic single-wafer up to 150 mm MNC

- ICP Gen. up to 2000 W - 13,56 MHz

- RF Gen. up to 600 W – 13,56 MHz

- Gas Lines: SF6*, C4F8*, CF4, O2*, He, Ar. (* Duplicate massflows)

- 2 mechanical pump 1 turbomolecular pumps

- Temperature: -15ºC up to 80ºC. He-backside thermalization

- Bosch process

- Layer etching: Silicon, SiO2, Si3N4, polyimide, graphene

SENTECH SI 500 SI

- Automatic single-wafer up to 150 mm MNC

- ICP Gen. up to 2000 W - 13,56 MHz

- RF Gen. up to 600 W – 13,56 MHz

- Gas lines: SF6*, C4F8*, O2*, He, Ar. (* Duplicate massflows)

- 2 mechanical pump 1 turbomolecular pumps

- Temperature: -15ºC up to 80ºC. He-backside thermalization

- Bosch process

- Layer etching: Silicon, SiC

SENTECH SI 500 CL

- Automatic single-wafer up to 150 mm MNC

- ICP Gen. up to 2000 W - 13,56 MHz

- RF Gen. up to 600 W – 13,56 MHz

- Gas Lines: Cl2, BCl3, Ar, N2, O2, He

- 2 mechanical pump 1 turbomolecular pumps

- Temperature: -15ºC up to 80ºC. He-backside thermalization

- Optical end point detection

- Layer etching: Group III-V compound semiconductors

ALCATEL GIR 160

- Parallel plate RIE manual single wafer up to 150 mm

- RF Gen. up to 500 W – 13,56 MHz

- Gas lines: SF6, CHF3, CF4, O2, He, N2

- 1 mechanical pump 1 turbomolecular pump

- No control temperature

- Layer etching: Silicon, Polysilicon, SiO2, Si3N4, SiC, TaSi

Download the tecniques and capabilities of the Dry Etching Area

Check the Dry Etching Area

Dry Etching Team

- Roser Mas (ext. 435570)

- Carles Mateu (ext. 435569)