Thermal Characterization Laboratory

The Thermal Characterization Laboratory covers all aspects concerning experimentation in thermal management, local electro-thermal characterization, and reliability/ruggedness studies addressed in IMB-CNM’s Power Systems Integration and Reliability research sub-line. In addition, these activities could find synergies with other fields dealing with the electro-thermal characterization in the nano-microelectronic scenario.

Main activities

In this framework, the main activities of the Thermal Characterization Laboratory aim at:

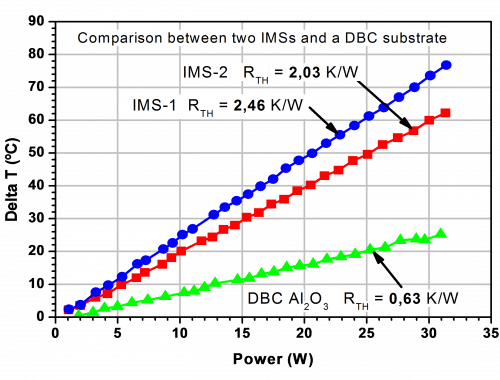

- Thermal management design and assessment at system level of power devices or systems (thermal conductivity extraction, temperature measurement for simulation assessment),

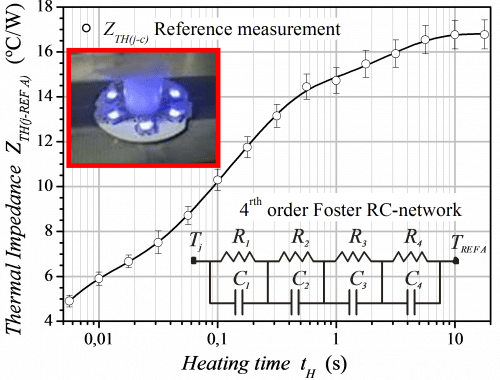

- Thermal characterization of packaged devices and systems (thermal impedance and resistance extraction);

- Local electro-thermal characterization at die level (applicable to low power integrated systems, e.g. Systems-on-Chip)

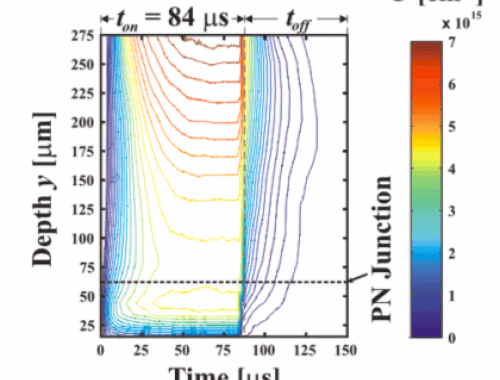

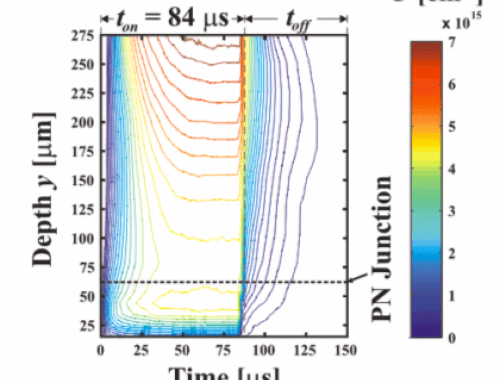

- Optical methods for depth-resolved characterization at chip level: Free-Carrier Absorption, Internal IR Laser Deflection, Fabry-Perot Interference,

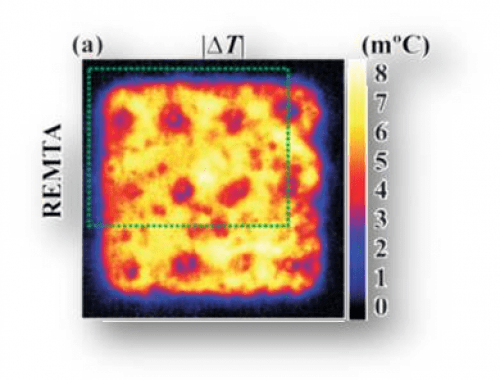

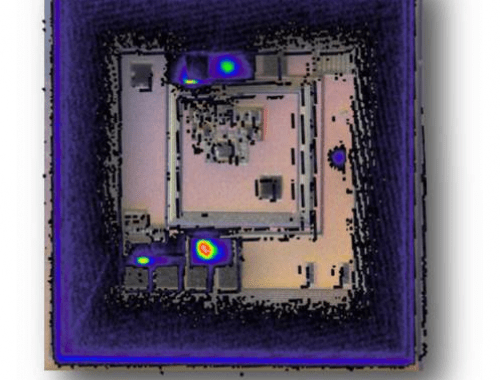

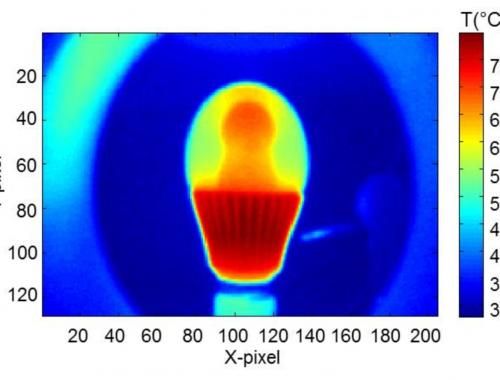

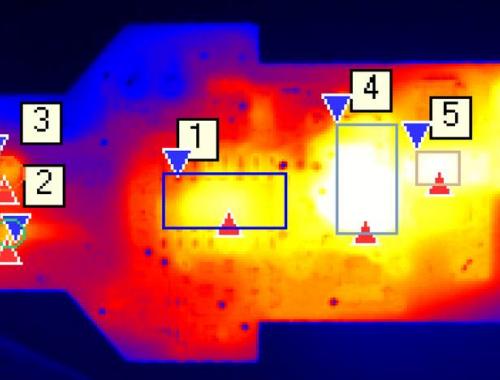

- Surface-resolved electro-thermal characterization: IR thermography, Liquid crystal thermography, CCD-thermo-reflectance thermography.

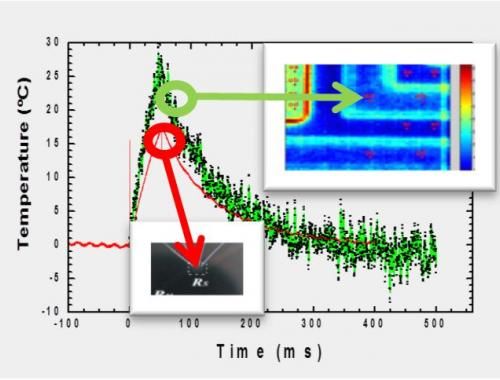

- Debugging and design for ruggedness of new devices and monitoring electrical and thermal performances degradation due to ageing or overloading events:

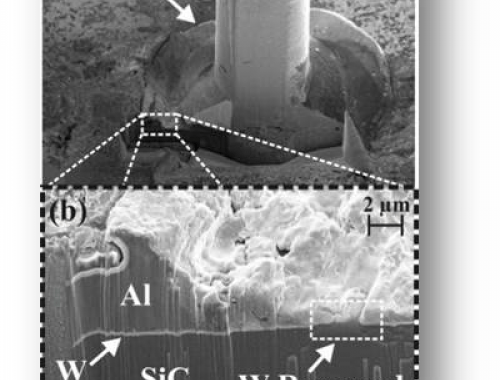

- Location of physical failure signatures at die level,

- Thermal performances degradation due to packaging ageing, local electrical degradation of the device.

- Study of modulated heat sources by lock-in detection for non-invasive evaluation of structural defaults, extraction of Figures of Merit in Frequency (FOMs) from IC/device internal nodes, and local physical parameters in devices

Techniques

- Analysis of thermal behavior of power devices and systems (hot-spots, thermal coupling, reliability, modeling, etc.), using specific thermography techniques (IR detection, CCD-thermo-reflectance, or Fabry-Perot interferometry).

- Thermal parameters extraction systems for integrated power systems thermal management (modules, substrates, modeling, simulation parameters, etc.): material thermal conductivity and packaged devices thermal impedance and resistance measurements.

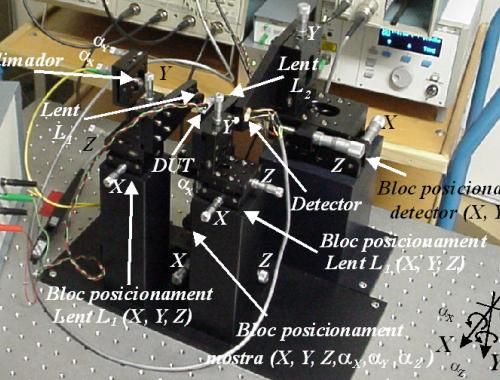

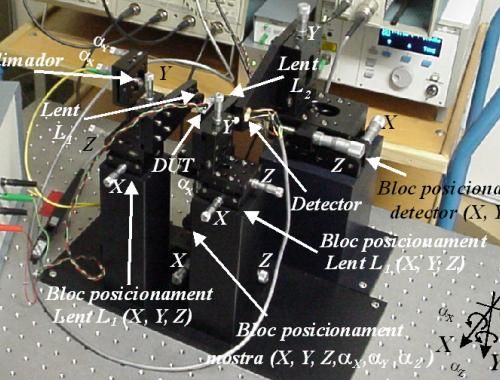

- Analysis of electro-thermal behavior at device level ("hot-spots", reliability, carrier lifetime, modeling, etc.) using techniques based on optical deflection (IIR-LD), absorption (FCA) and interferometer (FPI) of an IR laser beam.

- Failure signature location and microelectronic systems debugging by sensing thermal fields.

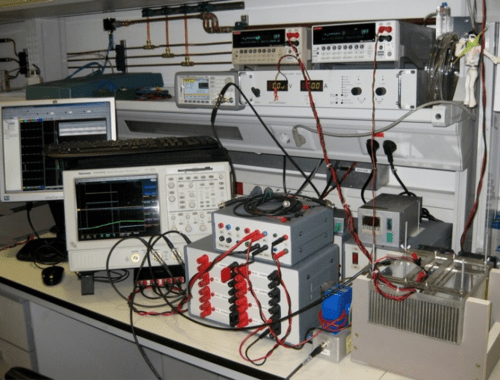

Equipment

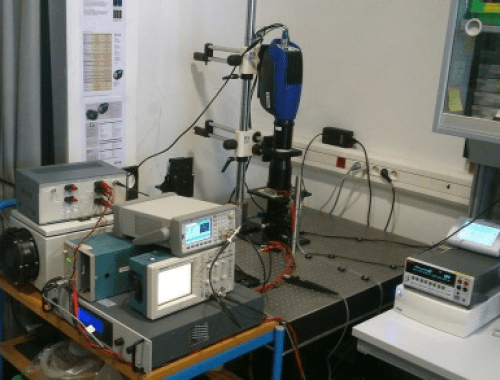

- Infrared Thermography measurement equipment

- Infrared camera FLIR SC5500 in optical bench

- Infrared camera AGEMA Thermovision THV-900

- Macroscopic and microscopic lenses (minimum spatial resolution 6 µm)

- Lock-in thermography set-up

- Depth-resolved Electro-thermal characterization

- Measurement of internal temperature and free carrier concentration, as well as their gradients

- Thermo-reflectance thermography system

- High spatial resolution thermography

- Thermal conductivity measurement system

- KTH measurement of materials involved in power packages

- Thermal resistance/impedance measurement system

- Measurement of RTH / ZTH using thermo sensitive parameters

Contact person

Miquel Vellvehí