MicroEnergy Sources and Sensor Integration Group (MESSI)

The aim of the group is to contribute with new micro-energy and smart sensing devices to important long-term challenges such as “Healthier Citizens” and “Net Zero Human Impact”. Within this general framework, different lines of research are addressed: In the micro-energy field, we cover harvesting (thermoelectricity) and generation/storage (micro-fuel cells / biodegradable batteries) activities. In the sensing field, we focus on systems that allow identifying gases or biomarkers. The microintegration feasibility of both sensors and energy sources to achieve autonomous systems is another interest of the group, using standard silicon technologies and rapid prototyping and additive manufacturing. Finally, the group has recently incorporated research into resistive switching devices based on high permittivity thin-film dielectric materials for the development of RRAM memory cells and memristors with potential interest in various application areas such as electronic synapses for neuromorphic applications, or for integrated circuit safety applications.

Contact Person

More info

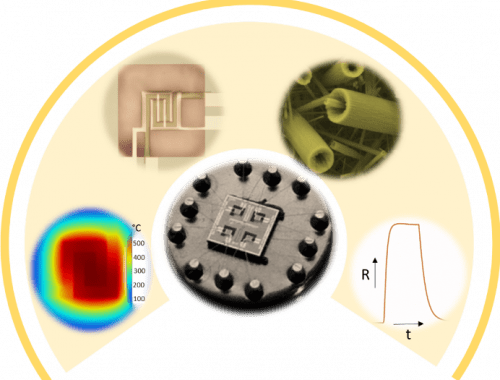

The generic objective of our group is to make use of micro-nanotechnologies to obtain micro-nanodevices built from microstructures with an architecture that confers them an added functionality (resonant structures, thermal isolated structures, 3D topography...) and on occasions the synthesis of sensitive or functional materials that allow those microstructures to interact with the environment. In this way, transducing physical or chemical phenomena into electricity, both information and energy can be obtained from the surroundings these elements are placed in, leading to sensors, micro-energy sources and, eventually, to autonomous or self-powered sensors. The materials used are typically those commonly related to silicon technology (IC and MEMS), recently complemented with alternative materials such as functional polymeric materials or polymer/paper-based structural materials and their associated low-cost technologies. In all cases, technologies are scalable, and materials abundant and environment-friendly so that a cost-effective, large volume and sustainable production of such elements is possible.

Micro-energy related devices

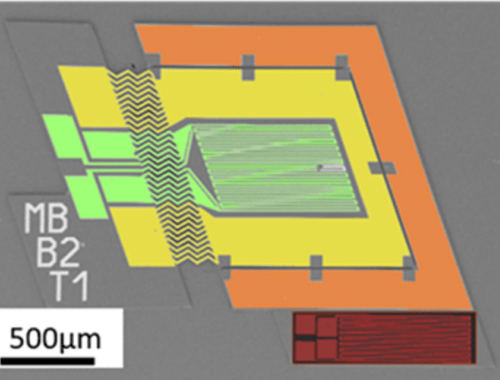

Progressing in the development of thermoelectric microgenerators based on the microfabrication of a thermal suspended platform, a thermal microradiator and the monolithic integration of silicon nanowire arrays as thermoelectric material.

Thermoelectric harvesting

For long-term scenarios, we consider thermoelectric energy harvesting. Particularly, silicon planar microgenerators for IoT applications based on Si-based nanowires are being researched towards an increase of device density and the successful integration of miniaturized heat exchangers, so that a useful energy/power can be extracted. Progress is on the development of all-silicon thermoelectric microgenerators based on the top-down microfabrication of a thermal suspended platform with minimal losses, the monolithic bottom-up integration of silicon-based nanowire arrays as thermoelectric material, and the physical assembly of a heat exchanger that maximizes the temperature difference attainable across the nanowires when the system is placed in a hot surface. A similar technological approach is being used for exploiting and characterizing thermoelectric thin films (as-grown, or even while-growing, using the 3w Völklein method with sub-monolayer sensibility) or devising devices that could both harvest and store micro-energy of thermal nature.

Contact: Luis Fonseca (luis.fonseca@imb-cnm.csic.es).

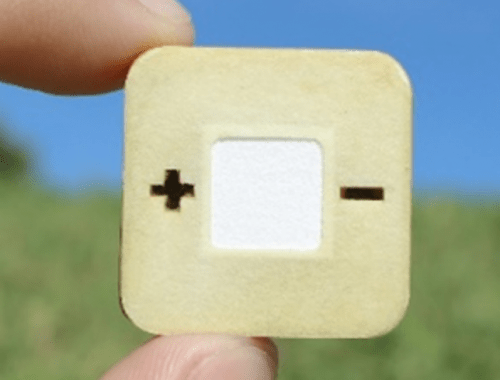

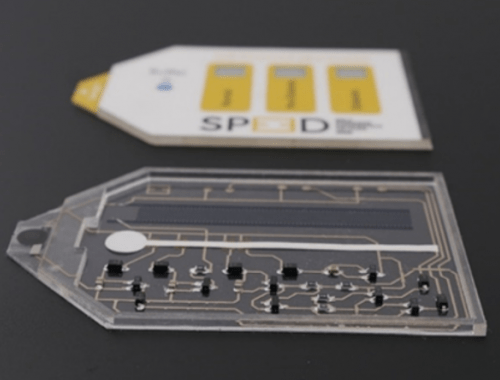

Disposable micro-energy storage and self-powered sensors

On the other hand, rapid prototyping technologies and low-cost and biodegradable materials are used to develop a new generation of disposable and low environmental impact fuel cells and batteries able to offer a sustainable alternative to state-of-the-art battery technologies for short- and mid-term energy autonomy scenarios. They will provide simple, reliable and clean power either by means of small footprint environmentally friendly batteries able to power portable sensing systems or by integrating small fuel cell into an upcoming generation of smart paper-based single use and self-powered engineered devices. The fuel cell is conceived to deliver the power required by the application for a limited period of time, and to be disposed of afterwards, by directly scavenging it from the fluid to be tested in the point-of-care device (namely blood, urine, saliva, sweat). The core of this research topic takes advantage of (i) the electrochemical approach, to extract energy and develop self-powered devices, (ii) the choice of technologies and materials, for sustainable and low cost production, and (iii) the use of paper capillarity, which eliminates the need of pumps when a flow of sample or reactants is required. This extremely simplifies the device and the associated driving electronics, which could be even printable.

Contact: Neus Sabaté (neus.sabate@imb-cnm.csic.es).

Gas sensing microsystems

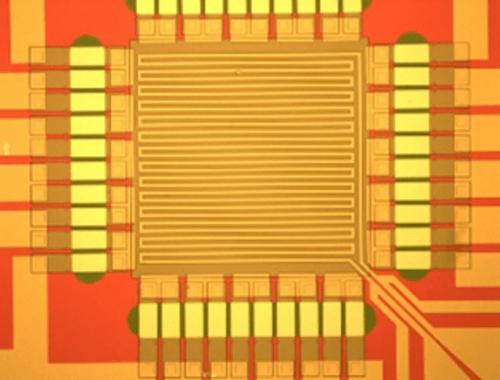

Finally, we explore new gas detection principles and routes for better selective and low-power consumption gas sensing microsystems. Our approach includes the synthesis of more performant gas-sensitive materials (e.g., surface modified metal oxides based on ZnO, WO3, Fe2O3) via scalable chemical routes (e.g., aerosol assisted chemical vapour deposition) and the integration of multiple sensing elements into monolithic arrays based on rigid (e.g., silicon) or flexible (e.g., polymers) substrates. Our recent efforts are focussed on the combination of resistive and optical responses of such materials and structures to obtain high-performance smart gas sensing microsystems at low cost with durable and fast-reacting characteristics so that they can be used ubiquitously for monitoring gases/vapours of interest in the environment and industry. Thermoelectricity is also considered as a working principle for the development of flow gas sensors. Also in this case, low cost technologies based in polymers and standard-Si technologies are used.

Contact: Stella Vallejos (stella.vallejos@imb-cnm.csic.es).

Memristors based on high-k dielectrics

- Resistive Switching phenomena in high-k dielectric-based MIS and MIM structures. Electrical, physical characterization and modelling of memristors.

- Investigation and modelling of the variability sources, noise, radiation effects and aging mechanisms that can limit the reliability of Resistive Switching devices.

Contact: Francesca Campabadal (francesca.campabadal@imb-cnm.csic.es).